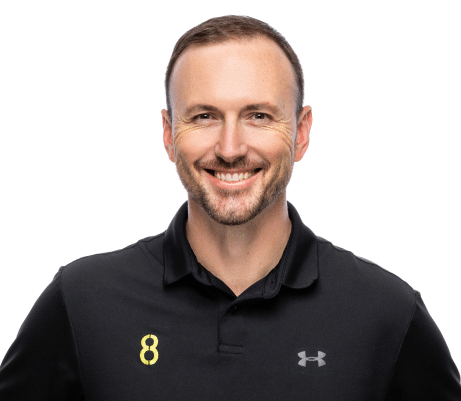

In this episode, we speak with Graeme Welton, Founder and Managing Director of Flow Software. We dive into tech start-up strategies and entrepreneurial advice for engineers. And how the Flow product was born to transform and make data available to decision-makers.

Learn more about Flow on their website.

Transcript

00:04

Jaco

Hi everyone, and welcome to another podcast of the Human and Machine show. Podcast show. I suppose it is. It feels like it is, lady. This is our second one. We’re very excited for all the support we’ve received. We had lots of comments and suggestions. Thank you for that. If you missed. Last week we spoke work with Brahm Fenter, who is with advances, the integrated advances, who shared some really quality insights in terms of how they have been operating and how they have been just doing business and delivering the kind of value and support that their customers expect during this time of lockdown and Covid. So really good insights by Brahm last week. So if you missed that podcast, make sure that you listen to that one.

00:50

Jaco

The Human and Machine podcast is, of course, where I and my co host Lenny, we talk about all things industrial, tech and manufacturing, specifically from a south african perspective, as well as some global trends that we’re seeing. And hopefully helping you make sense of what is available out there and how you can improve and how you can just get better understanding of how the world of tech is shaping the industry as it is with manufacturing and mining as well. So with me is, of course, Lenny, co host, Lenny, how are you doing? Good evening. Good.

01:26

Lenny

Quite interested for today’s topic. I think it’s one of these topics that’s also close to my heart, the topic about the notion of information. We live in an age where information, I think, is everything, and not just from our social aspects, but also in our case, from the manufacturing environment. And it’s very interesting to see how information can play a pivotal role in our manufacturing sites and environments that we have here. So I’m very pleased about this session that we’re going to have today.

01:53

Jaco

Definitely, there’s almost a notion that information is a currency.

01:57

Graeme

Exactly.

01:57

Jaco

And yeah, that’s a very apt topic at the moment. And I think, especially with the guest that we have with us today is really someone that started a business, a tech startup, I suppose you can call it. I’m not sure what the term is, but started a business on the topic of information, how we collate that, how we gather that, and how do we present that. So, yeah, who do we have?

02:20

Lenny

Well, I’m very pleased to introduce Graham Welton, the MD of Flow software. Now, flow software is a software development house, and they’ve got a product they call the flow information platform. And the platform is really geared to consolidate and contextualize all of these different silos of information that we can find, especially in a manufacturing environment. And I think one thing that we’ve seen is that data in a manufacturing environment is quite specialized. It’s huge amount of data that’s been generated by machines and even by people and by different systems on a manufacturing environment. And how do you collate all of that? How do you make that information available for everybody, and how do you make actionable sense of that data so that at the end of the day, that you can actually make better decisions on actually operating your manufacturing facility.

03:09

Lenny

And that’s what the flow platform does. It’s a great tool. It helps us to actually understand and mine this magnitude of data that sits on our manufacturing environments to make sense of it all. And actually, at the end of the day, it’s all about return on investment. You spend millions of rands on machines to actually run your manufacturing environment, but is it actually doing what it’s supposed to? And this is a great platform to actually help us to do that. So without further ado, Graham, welcome. Thanks a lot for joining us.

03:38

Graeme

Well, thank you very much for having me, guys.

03:40

Jaco

Yeah, nice to have you. It’s nice to see you as well. We’ve spoken over the past few weeks, but we haven’t really seen each other and it feels like it’s a privilege to be able to sit together.

03:52

Graeme

Absolutely.

03:53

Jaco

Especially during these time. But thank you for accepting to join us for some conversation. It’s a very relevant topic at the moment, especially where people are having to do so much more with so much less in a number of ways. So very relevant topic. But I think it’s also very fascinating to me that I really want to get into a little bit more with you is start a business, create a technology, productize it. All of that is obviously very possible. And South Africa has had some really good examples over the past years of tech startups, some really phenomenal businesses that have come out of South Africa. But talk us through that a little bit. I mean, that’s not something you just decide overnight we’re going to create a product, start a business and develop it in South Africa. What was that?

04:41

Graeme

Absolutely. So, well, first of all, thank you for having me. Great to be on your show. And thank you, Lenny, for the introduction. Yeah, so it goes back a number of years. It goes back probably to the mid 2020.

05:06

Jaco

I think it’s 2000, the naughties.

05:10

Graeme

Exactly. So roughly 15 years ago, I was still working at south african breweries. My role was very much in the process control space, got quite involved in the batching processes with standards like s 88 and what I started seeing from my internal customers as an internal service provider started seeing how much they relied on information, and I became as the leader of the department responsible to provide that data in a way that they could actually make use of it, they could make informed decisions out of that data. And so it became a process of understanding how to convert that process control information or data, that batching data, first of all transforming the data, and secondly then being able to visualize the data in a way that they could use it. It started all the way back then.

06:17

Graeme

I then left breweries around 2008, I think it was 2008, and joined a system integrator company where I was able to use a lot of my process control, my batching knowledge. But I always had in the back of my mind the need for this data to information transformation, and through the years, the early years of working with the system integrator and working with other customers. So now I’m outside of the breweries environment and now I’m working with many customers and I saw the same problems, exactly the same problem that needed to be solved by all of these customers. And so it kind of kept on nurturing this idea that we need to do something, we need to create something that’s going to serve all of those customers.

07:17

Jaco

And obviously at the time, I mean, it’s no different to what it’s like today. There were obviously just a multitude of existing kind of solutions available out there that to some extent did provide some capability and functionality, but obviously not in terms of the vision that you had to that extent. Obviously prompting know, let’s create something based on the vision that we have.

07:41

Graeme

Yeah, exactly. And I think we saw a multitude of reporting tools, Crystal reports, Microsoft reporting services, tools that can be used to attach to the raw data and create some kind of visualization. And we actually saw an opportunity to turn that around a little bit. And I think that was where flow was born, because a very big part of what flow is, what the flow information platform is, it’s not so much about the visualization. Yes, that’s important, but what is more fundamental is the transformation of the raw data into something that is structured, that’s contextualized, collated into a consolidated repository, and that is your single version of the truth. And that’s what’s actually the foundation of what flow is. And we didn’t see many products on the market that were doing that.

08:48

Lenny

Not in our space, not in the manufacturing space. I mean, data is one thing or information is one thing. Information is in way different industries. And I think Graham, with your process knowledge and your experience in the manufacturing environment, that actually helped you to guide to make this tool available for an hour industry where we see a lot of manufacturing data. And we actually now understand manufacturing data. And the tool is very geared to very simple and easily turn manufacturing data into quality information, which is a difficult concept. It’s not as plain simple as you can think.

09:22

Graeme

Absolutely.

09:24

Jaco

That information today, that’s such a crucial piece for the entire supply chain. So many decisions are made based on that data. So the better that data, and the better the context with that data, the better your supply chain, ultimately.

09:38

Graeme

Exactly.

09:38

Jaco

And that’s become more and more important.

09:40

Graeme

And I think to add to that, it’s also the different levels within an organization. If you’re at the coalface, you are making decisions on a minutely hourly basis. And if you’re in the boardroom at the other end of the scale, you’re potentially making decisions weekly, monthly, much bigger time frames, time buckets. So from the boardroom all the way down to the coal phase, we’re looking at aggregated data. We’re not looking at the real time data right now. Not for the most part, certainly, to steer an organization, to steer the ship. You’re not looking at real time data, you’re actually looking at trends, you’re looking at aggregated data, you’re looking at calculated KPIs. So, to add to your point is it’s different levels in an organization, but it’s also different time periods, different intervals that decisions need to be made.

10:43

Graeme

And that’s where flow was built from the start. It was built with those different time intervals as core foundation to the product.

10:52

Jaco

Yeah. So I want to get back a little bit to the starting of a business, I suppose so. Good process background, good understanding of the needs and the requirements. Clear vision. That’s a little bit different to let’s start a business and let’s develop a product. That was probably quite a daunting task.

11:12

Graeme

To undertake, and it was, and I think any young entrepreneurs out there, the one biggest piece of advice I would give them is to make sure you’ve got a good partner or set of partners, because I was very fortunate that I had the partners in my business to be able to bounce ideas off, to be able to validate these ideas, and to buy into the vision and then work together towards actually delivering that. So in a way, I think I’ve been so lucky that I’ve had that it wasn’t such a big deal when we actually started flow software, because we had that backing. We had like minded thoughts and strategies around starting up a business. But yes, it took a long time.

12:11

Graeme

It was a product that we built a version, one of which was pretty basic, had the foundation functionality built, but it was difficult to get it out. We started with one customer. Luckily that customer grew it to multiple sites, and we realized quite quickly that weren’t going to be able to get out there and sell it and market it ourselves. We were a bunch of engineers, had very little knowledge of selling something and marketing something. We were lucky with this one customer, which then grew into two customers, that then grew into three customers. We kind of had three customers that were demanding the product and they were demanding the growth of the product. We used that demand to actually convince another company to take it on and to basically outsource the selling and the marketing of the tool for us.

13:19

Graeme

And that left us to focus on the product and developing a good, solid product.

13:24

Jaco

The core focus.

13:25

Graeme

The core focus.

13:26

Jaco

And that’s how you get your adoption curve.

13:28

Graeme

Exactly. And I must say we started with this model fairly quickly, probably within about a year or two of starting flow, and we approached wonderware Southern Africa at the time. Their name has changed subsequently, but the team there, guys like Michael Aplastria, Dion Fernart, Aaron Stefanbe, those guys embraced flow and what it meant, and they also identified that it filled a gap within their product offering, which they are slowly closing that gap. But at the time they embraced it and they were absolutely fundamentally important in the growth of flow. And I’m so grateful for that. Yeah. So it’s taken a long time. It’s not like it happened overnight. I mean, we’re eight years plus down, nine years down, and we’re still pushing hard.

14:32

Jaco

So it’s an overnight success that took eight years. Exactly. What is that? I’m keen, Lenny. I know you’re a very keen. I don’t want to call you a developer, maybe that’ll box you, but what does that look like in terms of, I don’t know, language selection platform? Where do you find developers? Where do you find talent? Where do you find people that can help you build this vision? Because you can’t do that on your own. Absolutely not. You need a very good, solid team of people to work on that. Where do you find those people? I wouldn’t know where to start.

15:02

Lenny

Yeah. I think one thing is quite key to understand is there’s a lot of developers, right, if we now take the developer space, there’s a lot of guys that actually developed, that can develop you a software platform and get the product rolling. But I think one key thing in this case, is it’s not just the developer, it’s actually someone that also understands the manufacturing environment that we play in. The type of data and the type of instruments and tech that sits in our industrial space. You need to understand that, you need to understand what these different types of machinery generate from a data perspective, you need to understand protocols, you need to understand that. And I think that skill is special.

15:45

Lenny

The skill of a developer plus the knowledge and the context of manufacturing, the space of manufacturing, that is something that’s not very easily to find. So yeah, it is a challenge. I do believe it is a challenge to find people. The industry is also very small in South Africa. We’re a handful of engineers that play in this automation space, yet alone having still capability to develop something. On top of that, everybody knows everybody as well. So yeah, it is quite challenging to get the right person with the right skills to impart on such a topic. Other thing that I might also want to mention, and I think Graham kind of mentioned it, if you’re entrepreneur and you want to go into this thing, is obviously a key thing, was also to keep your team lean, right?

16:37

Lenny

Don’t try and explode to now all of a sudden try and get marketing people on board, et cetera, because you’re starting out this company. I think that was also a very smart move is to say, you know what, I’m going to focus on the software development, make sure that the product that I’m delivering of great value, and then let the marketing and the distribution falls onto another company or another umbrella so that you can keep your focus on keeping a lean startup going forward and then really just embracing or making sure that the product is of great value.

17:06

Jaco

Focusing on the quality. As the saying goes, you don’t necessarily have to be first, but you have to be the best.

17:13

Graeme

Yeah, exactly.

17:14

Lenny

And one thing that we found is that it’s easier. I wouldn’t say it’s easy, but it’s easier teaching someone how to develop than to teach someone process knowledge.

17:25

Jaco

Yes.

17:25

Lenny

And I think that’s key is process knowledge. You get with experience, you get it from sitting on a site, understanding the process and how the information flow through that process. What we typically look at is we look at people with process or domain knowledge and development can be taught kind.

17:43

Jaco

Of on top of. Yeah.

17:46

Graeme

And I think to add to what Lenny’s saying is when we go out and actively recruit, we actually look for engineers, whether they mechanical, I’m actually a mechanical engineer, whether they electrical, computer, maybe a mixture, electromechanical, mechatronic, those are the kind of people that we actually look for. I think our entire team is made up of degreed engineers. And to Lenny’s point, we find it much easier to teach an engineer to develop. And if they’ve got industry experience in our domain, which is the industrial automation space, or the mining space, or the renewables energy renewables, or oil and gas, it’s much easier to teach those experienced engineers how to code their brains. Just get it. And the way they structure the code or the design, it just falls into place for their brains.

18:56

Jaco

Yes.

18:56

Graeme

It just works natural. It’s a good fit.

18:58

Jaco

Yeah, naturally.

18:59

Graeme

And so when I talk to young, maybe even school going kids about their careers, I will often encourage them to look in the engineering path if they’re interested in science and specifically the combination of electronic and a mechanical.

19:19

Jaco

Yeah, it seems like a niche that has become super important. Just looking at the manufacturing space today, in the manufacturing world, definitely. And it feels a little bit. Maybe I’m wrong, it definitely feels like there’s a little bit of a skills gap there generally in South Africa. And I think skills gap is probably a bit of a general term in many ways, the skills gap that many people refer to when they talk. Skills gap is something that we created as an industry. You expect a young engineer to walk onto a site, and because there is so many different solutions and offers and technologies at that site, you almost expect them to be proficient and be experienced with all of them, because that’s just how we’ve done those sites and how those sites have evolved. And it’s actually very difficult finding those people today.

20:15

Graeme

We do struggle and often what we will do, we typically don’t make use of recruitment companies because.

20:23

Jaco

Interesting.

20:24

GraemeWe prefer to have some kind of relationship with those engineers beforehand. Yeah. And then the word of mouth, obviously, that we might be looking and someone will apply.

20:37

Jaco

What is the thinking of engineers? I call them techies engineers. My favorite people by far. In an office environment, it’s always the part of the office where you’ll get the most banter from the most laughter from. Love. Working with engineers and techies. What does it look like working with a team of potentially 80% ADHD individuals? And you’re obviously very fortunate coming from south african breweries. I think at that time, south african breweries had a phenomenal culture. I’m not sure what that looks like today under ABMDev, being a much larger global organization, but the culture at SAB at that time was phenomenal. I think they had achieved a number of best Employer awards at the time starting a new company, bringing a bunch of techies on board. How do you keep everybody together, aligned, on board, focused on the same thing?

21:37

Jaco

What does that look like? Is that.

21:40

Graeme

Know, I think with engineers, it’s a little bit easier. Like Lenny said earlier, we started with a core bunch of engineers, and we’ve expanded as we’ve needed to. And only very recently did we bring in a marketing person. And I can tell you almost immediately, the decibel level in the office went up three or four times. When the marketing person came in with a bunch of engineers, it’s actually okay. I think what you will find is generally, everyone’s got pretty strong opinions in terms of direction and strategy, but we make it work. We make it work. And I think that actually brings a lot of strength to the path that we take with our product.

22:35

Jaco

It’s a very good point. I think in many ways, you can’t expect the team to slow down because you want to lead because you’re expecting them to create and to be innovative. So you can’t expect them to subdue that because you want to lead and go with your vision. You want them to do that naturally, while at the same time keeping in mind that you’re productizing something, which in itself must be a massive challenge to productize something with version controls and documentation and all of those elements that I think very often people don’t think about when they think about the very romantic notion of starting a new company. And especially in the tech space, there’s a lot of those sort of things that they don’t.

23:21

Lenny

And not just that aspect of it. I mean, we’re talking about a software product that you’re putting in the industrial space. And Graham mentioned about it, there’s so many different verticals in the industrial automation. There’s oil and gas, there’s food and bed, there’s mining, there’s material handling. Now, you also have to cater for a product that’s generic across the entire kind of vertical space.

23:45

Jaco

Yes.

23:46

Lenny

So, yeah, it is quite challenging to also now create something that’s generic enough that will fit for each and every one of those industries information needs at.

23:55

Graeme

The end of the day. And the other thing that we find quite tricky is the future proofing of functionality. And I think we have learned our lesson one or two times in the past where we have made a decision too quickly and we’ve put something in and it doesn’t quite work. And now we have to maintain that forever. So it’s taught us by no means did we have a good idea of what were doing in the beginning in terms of productizing something. And we’ve kind of stumbled along in the beginning and we’ve found our way and we’ve had to up our internal processes, our documentation. It’s been a huge learning curve for the whole team.

24:46

Jaco

I want to quickly ask you about, I think, Lenny, you mentioned to me that there’s some north american scope in terms of further growth. Obviously, well established product, good install base, good customers, supporting the community, built around flow. What are some of the future mean? I know that North America is definitely a market that you are already in, very much involved already. What are the future plans for flow? Where to next?

25:21

Graeme

Yeah, so we’ve been very fortunate in Africa, as I mentioned, we’ve had quite a few companies and they’ve actually expanded into Africa, or they’ve had facilities in Africa. And so what that’s provided us is kind of a springboard into other markets. It’s given us enough revenue to start exploring other markets. And so what we decided to do probably two or three years ago, was start investigating the US market, specifically the US market, because of its size, because of its industrial capacity, its manufacturing capacity, renewable energies is massive in the US. What we did was we started up effectively a sales office, sales and support office, actually, in Austin, Texas.

26:22

Jaco

I was going to ask about that because you obviously don’t want to. If you have a core development team, you don’t want to split that core development team. I would imagine it’s quite crucial for that team to work together and operate as a unit. And especially now with lockdown, it’s made it, I suppose, even more challenging for that team to work together. You typically don’t want to split the core development team.

26:46

Graeme

So it’s actually an interesting question because I never thought we could until lockdown.

26:51

Jaco

Interesting.

26:52

Graeme

And this last four months, where we’ve been working from home exclusively, we’ve had to make it work. And I’ve actually found that it’s worked very well. It’s forced us to be a little bit more structured. We’ve had to use the tools that are available to us, that we can see each other, that we can whiteboard ideas with each other. And it’s actually worked. And it’s changed my mind. It actually has made me think we could potentially split the team, the development team, because we do have some of the team who’s very interested in moving to the US.

27:29

Jaco

Yeah, for sure.

27:30

Graeme

And we have some members of the team are happy to stay in South Africa and continue. So we want to be able to provide those opportunities for our team members and we’ll see how it goes. But yeah, coming back to the US market, a large market, the right industries that we can feed. English speaking at the moment, the flow information platform, the configuration environments, it’s all English. So it would be difficult for us to move into South America. A lot of Europe would be difficult. So we have focused on the US and part of our development pipeline is to make it multi language, which would then allow us to start expanding into other markets as well. I think the more english speaking areas of Europe would be good. The UK, obviously. So there’s opportunity for us to look there.

28:31

Graeme

Australia, New Zealand, absolutely are opportunities for us to expand. But I think what we will probably do is we will use our hub in Texas to distribute to those other areas.

28:46

Jaco

Texas, lovely place.

28:48

Lenny

Graeme, maybe. One question I have on that is obviously you’ve got great traction in Africa, in some large multi site kind of organizations that’s also global organizations. And for me, as an engineer, marketing is like a black box of tricks and pull a rabbit out of a hat. So for me, marketing is.

29:09

Jaco

Sometimes you pull the hat out of the rabbit.

29:11

Lenny

Yeah, I’ve got great respect for marketing people, but my question that I have is, do you think that the information challenges we have in Africa, obviously we’ve got our own set of challenges, especially around utilities, management, et cetera. Do you think it is the same in potential other spaces? Do you think the need for information changes potentially, like in the US market? And is it at that point where you kind of realize, listen, we probably need to start doing our own little marketing activities to understand that market a bit better. So just maybe a little bit of feedback on that, what your thoughts are.

29:50

Graeme

So I think certainly in Africa, resources are absolutely scarce. And so the drive or the demand for a product like flow is naturally there because it helps people see the information and try and improve their efficiencies, reduce their waste, reduce their usages of resources, water, electricity, et cetera. What we’ve gone over to the US assuming is that we’re going to see the same thing there and we haven’t. We’ve seen that because there’s more abundance of resources. The demand for a tool like flow is not quite the same, but I’m optimistic that’s going to change. I think we are going to see a higher demand for products like flow because resources are getting more expensive, they’re getting more scarce.

30:50

Graeme

So, yeah, I definitely think we, and we’ve actually embarked on some marketing activities which will explore the US a bit more for us and to give us a bit more insight, so. Absolutely, Lenny. Yeah, we’re on that path. It’s early days, but yes, I think.

31:06

Lenny

On that point, I mean, we’ve mentioned it right at the beginning of the call that information is becoming a commodity. It’s almost know you can buy it.

31:14

Jaco

Right.

31:15

Lenny

Facebook is buying your information and selling it to whoever. But I don’t want to go into think. Yeah, I think information in the manufacturing mean we’ve been talking about big data and what big data can bring for a long time. It’s a topic that’s been around for quite a while. But I do feel that we’re in the right time, especially now with lockdown as well, where the need for quality information is more critical than ever.

31:42

Jaco

Absolutely.

31:42

Lenny

And that information becomes a commodity. It becomes valuable, it becomes actual dollars, it becomes rands and cents. It becomes something that’s tangible that you can now actually use to determine return on investments of pieces of equipment and what you are doing every day from, as Graham said, try to reduce your waste and everything. So, yeah, I think Graham, in that sense, information is becoming more and more prevalent in the manufacturing space.

32:08

Jaco

What does that look mean in the manufacturing and in this world of ours, how does that flow of information look like? It’s collected, it’s collated, it’s contextualized, it’s provided. What is that for some of us, that maybe some of the listeners on the podcast that’s not that familiar with what that looks like and the systems that are involved, can we do like, maybe a quick two minute recap of.

32:29

Graeme

What that looks like? I guess there’s a number of places, systems, devices that are generating data. So edge devices, they are generating data. Plcs that are controlling systems, batching systems that are controlling systems, they’re all generating tons and tons of data all the time. What we do typically is we make use of, I’ll use a generic term, a historian. Now, what a historian is a purpose built time series data capturer. So, it takes that data that’s been generated by the edge devices or the PLCs and whatever, and it starts storing that at very high resolution. So sometimes milliseconds. And what we do with flow is we take that high resolution data and we perform aggregations on it.

33:29

Graeme

So, for example, we might take a time weighted average for an hour, and that gives us one data point that is meaningful to somebody up the chain that needs to make a decision. But it’s distilled from maybe 10 million data points for that hour, for example. Sorry, not 10 million, maybe 10,000 data points for that hour. Now, we started with a very well known historian, which is the wonderway historian, incredibly popular, very powerful historian. And we built flow in a modular kind of structure framework, which allowed us to very easily and very quickly spin up new connectors. And as soon as we moved across to the US, we started seeing other historians, other data sources.

34:27

Lenny

And we struck.

34:28

Graeme

Up some relationships with these guys. So one of them was Canary Labs. They produce an incredible historian, the Canary historian, and we very quickly were able to create a native connector that pulls the data from the Canary historian. And to this day, we’ve got a fantastic relationship with them. The other one that comes to mind is ignition. Ignition is a fairly new company in the process control and ScaDA world, and they have a historian as well. And were able to, again, spin up a data collector for their historian.

35:06

Jaco

So that ability to very quickly and easily connect to multiple different disparate data sources is quite key in terms of the progression of the product.

35:16

Graeme

Absolutely. I think, yeah, I’d go as far as to say that’s kind of our magic source. That’s what’s given us the ability to collate data from disparate data sources so quickly. And I can’t take credit for that, because one of our developers who built this framework started this thinking and this process quite a long time ago, and all credit to him for taking that route. It’s been fundamental to the growth of flow.

35:49

Jaco

Okay, fantastic. Any advice for young entrepreneurs, young developers? Again, we’ve had these incredible success stories of tech startups in South Africa. I think of companies like Skynemo, and over the years, there’s been some phenomenal tech startups. It seems like the south african engineering community has developed a knack for delivering these companies. Any advice for any young entrepreneurs, young people in our industry, specifically young engineers, based on your experience and background?

36:24

Graeme

Yeah, I mentioned it earlier. I think for me, the biggest one is to have the right partners. I think as long as you’ve got, even if it’s just one partner, you can share the load, because it is quite daunting getting started. The ability to just bounce ideas off somebody who’s got skin in the game with you, because it’s not just maybe your parent or a friend who’s giving you advice, who doesn’t have skin in the game. You want to have that. I think that’s an absolute fundamental. I certainly take my hat off to people who have started businesses on their own, because it must be really hard so that’s the first thing. The other thing is, and Lenny, you alluded to it earlier, you’ve got to really focus on your product.

37:21

Graeme

You’ve got to marry what your product does to the demand of potential customers. And you’ve got to just stick it out. You’ve got to get it in at a customer. You got to try, you’ve got to use that customer. It’s maybe not the right way to say it, but you’ve got to build a relationship with your customer that they are happy that you are testing new functionality and providing them. Just pushing it a little bit every single time, so that you eventually are able to then start sharing that new functionality with other customers. So keep on pushing the boundaries in your product, little bits at a time, and build the relationship with your customer that they do have some patience with you, obviously also acknowledging that they are investing in you. So you’ve got to give them something.

38:17

Graeme

Focus on the product, focus on what you do well. The core, if you don’t do marketing well, if you’re not a natural salesperson, don’t try and do that. Try and find somebody who can partner with you that can do that part. I’m an engineer and I love getting my hands stuck into the code and actually designing. And I’m not a marketer, I’m not a seller. So that’s what I wake up to every morning. I wake up wanting to get out there and get a little bit more, push that product a little bit more. And I suppose that’s my passion and I’m lucky that I have that and I can wake up wanting to work every day.

39:05

Jaco

Yeah, fantastic. That’s flow. Definitely helping to bridge a gap between man and machine and playing information, I suppose playing such a massive part in just empowering people that work with the tech and helping them to improve processes. Great story, Graham, well done. I love the fact that this was brand new at South African. You have a young team of engineers on board and just a fantastic success story. And from the sounds of things going global. So well done, Benny.

39:40

Lenny

Perfect. Yeah, maybe very last notion. Just a little bit on the future. Graham, what do you see? How’s the future for information and information management? Quite obviously, it’s not going to.

39:50

Jaco

That’s a tough question.

39:51

Lenny

It is a tough question. Sorry. I think information is just. Data is just going to become more.

39:57

Jaco

And more and more.

39:57

Lenny

I mean, we’re seeing edge devices pushing data with new protocols on the market just makes it so much more bandwidth efficient.

40:05

Jaco

It’s almost beyond information. I mean, it’s getting to the predictive kind of role. Predictive. What is the old saying? Knowledge is knowing that a tomato is a fruit. Experience is knowing not to put it in a fruit salad. Now we’re getting to almost like the predictive phase of information, where all that stuff is a given. Now it’s going to be interesting.

40:30

Graeme

Great. Yeah, I think it’s certainly underestimated the complexity of transforming data into information. And I can only speak for our domain, but there are a lot of proprietary data sources, like an ignition historian, like canary historian, and we’re able to connect into them and we’re able to transform that data into something that can be used in terms of our future. I think one of the, certainly there’s still some areas we need to get right in terms of transforming data even better and providing more context to our information. But I think a fundamental for flow and the future of flow is the collaboration component with other systems. So we’ve spoken about the collection of data, we’re collaborating with many interoperability sources.

41:24

Jaco

Exactly, that’s a term.

41:26

Graeme

But we don’t see flow as a black box of information. We see it as open, and we’ve gone to great lengths to actually make sure that data can be shared or pushed out to other systems. And I think that is our next real big step, is to expand the number of consumers of flow information, whether they are ERP systems, machine learning in the cloud, for example, business intelligence tools that might be already standardized within a customer and possibly even back to the real time world. If you’re doing a fairly complex KPI calculation in flow, you can potentially push that straight back to the operators on their scalars. So this collaboration between platforms, I think is the future of flow.

42:25

Jaco

Yeah, definitely. It’s almost expected. I can see it’s becoming an expectation that it just naturally will work together. Thank you.

42:36

Lenny

Sorry, the last thing, I think it’s also expected that everybody should be able to have information right there where they are.

42:42

Jaco

Yeah. At their fingertips, immediately available.

42:45

Lenny

So yeah, the more you can share, the more visualization and the more knowledge everybody in an organization has around the information and what’s available. It does not have to be just certain people that look at this. It must be shared, and I think it must be available to anybody in an organization to help them with their daily routines and daily lives.

43:05

Jaco

Yeah, certainly not a nice to have anymore.

43:07

Graeme

No, definitely not.

43:09

Jaco

Awesome, good point. Graeme, thank you very much for your time. It’s awesome chatting to you. Well done.

43:13

Graeme

Thank you, Lenny.

43:14

Lenny

Cool, thanks.

43:15

Jaco

We look forward to seeing what flow is going to deliver in the future. But great story so far. So that was Graham from flow software. Again, if you’re interested in being a guest on our podcast and chatting about all things manufacturing and operations, and again with a very specific south african lens, or if you have any questions for Graham or any other comments, suggestions, please send us an email at podcast at element eight co Z. We’re looking forward to your feedback and suggestions next week, Lenny. We’re quite excited. We want to speak to somebody at the coal phase of manufacturing and especially in the food and Bev industry, and just trying to understand what the last few weeks have been like and probably the immense pressure that those companies have been under. So next week we have. Can we share? Not yet.

44:09

Lenny

Well, we can share next week. We’ve got Franco Taron. He’s an engineering manager at one of our food and Bev clients, and he’s going to share a little bit around especially what they’ve done in the food and beverage space. If there’s anything that drastically that they had to change, especially now during lockdown and how they operate and how they utilize their information. So we are very excited to have franchise on the call next week.

44:32

Jaco

Yeah, I mean, those folks must have been through some really challenging times the last few weeks.

44:37

Lenny

Yeah. Margins in the food and beverage industry even before lockdown was tight. So there must been some great, we talked about last week. Out of despair comes great innovation. So I’m sure they’ve got some great, innovative stuff that they’ve been doing during this period to make their processes even better. So, yeah. Looking forward to speak to franchise next week.

44:57

Jaco

Fantastic. So that’s our guest for next week. Thank you for listening. Great. Thank you again for joining us. And we’ll see you on the next episode of the Human and Machine podcast. Thanks, everyone.