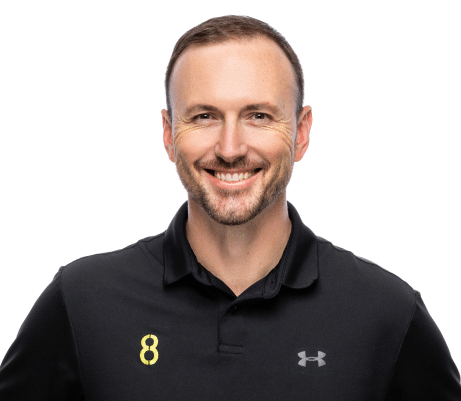

Online Educator and Industry 4.0 enthusiast, Walker Reynolds, shares his inspiring personal journey with us. And passion for helping save and create middle-class jobs by making manufactures more efficient; leveraging IIoT and Industry 4.0 principles. Walker shares what Digital Transformation actually is, and what it’s not. Why Digital Transformation only has a 10%-20% success rate and why OEE is a number you MUST be calculating.

SPEAKERs

Transcript

00:03

Speaker 1

Hello and welcome to the Human and Machine podcast. I’m your co host. My name is Jaco. I’m here with Lenny Smith. Lenny, how are you doing?

00:10

Speaker 2

Good to meet you, Jaco.

00:11

Speaker 1

I’m very well, thank you. Another week, another episode. If you missed last week’s episode, we spoke with Leandra Web Ray, who’s a data scientist with Decision, Inc. Just talking about what the data landscape looks like, the information value you chain. Fascinating chats and insights with a data scientist.

00:29

Speaker 2

Yeah, I think somebody might have a misperception of what a data scientist is. It’s probably someone you lock into a room that does math all day and you just slip them pizza underneath the door. But she debunked a little bit of those myths for us on the podcast last week.

00:43

Speaker 1

Yeah, that was really good chat with Leandra, and it’s also fascinating to speak to somebody a little bit more involved and formally trained on the data space and the data landscape. So that was really good. If you missed last week’s episode, there was episode 13. Can’t believe it. This week’s episode is episode 14. Obviously, it’s been an incredible journey so far. Thank you for all the suggestions, the comments, the support. Again, Lenny and I are not professional podcasters. We are just here to do a small little part in helping expose a little bit of what is available in the industry, some challenges people face, and just having conversations, really, Lenny, with some incredible people globally that are doing some amazing things. So this week’s episode, we are very excited to be chatting with Walker Reynolds.

01:29

Speaker 1

So I can imagine a couple of you have no idea who Walker is, and then I’m sure there’s a good few people that listen to our podcast that are absolutely ecstatic, that know exactly who Walker is. Bit of a legend, certainly for us in our world, in the industrial automation, manufacturing world. Walker is, first of all, Walker is the president and CEO at intellect integration as well as 40 solutions, and been going for a couple of years now as intellect solutions. I know there’s a couple of firebrand awards there, but really excited to chat with Walker today. We’ve been looking forward to this one for a couple of weeks and really just talking about, first of all, Walker’s passion for the industry, where that comes from. It’s almost very recognizable and it’s contagious. It is.

02:21

Speaker 1

We want to chat about just Walker’s history, introduction to the industry, some observations we definitely want to get his opinion on. Just his observations around the industry and how it’s evolved and how it’s grown with let’s call it Industry 4.0 and IIot. Yeah. So that’s what today is going to be about.

02:42

Speaker 2

Perfect.

02:43

Speaker 1

Walker, thank you very much for joining us. I’m not sure exactly what time it is at the moment in Texas for you, but thank you for joining us. Morning.

02:50

Speaker 3

Thank you. Good morning, Yako and Lenny. It is actually 853 in the morning here in Dallas. And since I’m up at 04:00. 04:00 a.m. Every day, this is actually halfway through my work day.

03:05

Speaker 1

Awesome. You’ve been up for a couple of hours then. I like that. We spoke with, who was it we spoke about? I think it was Travis. Also jumping onto the 05:00 a.m. Club bandwagon, I suppose all theory behind the 05:00 a.m., club, and it’s definitely been beneficial in terms of early morning productivity. But yeah. Thank you for joining us. So, Walker, obviously we don’t have a ton of time scheduled with you, but we would love to, first of all, just get a sense of your background. Where did it start for you? We often speak about this industry as the industry that we love, Lenny and I, and we’re very passionate about it. And we super excited when we find people that are equally as excited. So where did all of this start for you, and what does that journey look like so far?

03:51

Speaker 3

Well, I grew up. For me, the journey really starts in 1982. So in 1982 was the year that my, so for those of you who don’t know, we’re shooting this on October 5. And in the United States, October is domestic violence Awareness Month. And in 1982, I thank you for having me on in October. And in 1982, my mother was killed in an incident of domestic violence. This month. October is domestic violence Awareness Month. And it just so happens that her passing is really the beginning of my journey. So after my mom passed away, I moved to upstate New York in the States, which used to be a bastion for manufacturing in the United States, lots of really good paying jobs in traditional discrete manufacturing.

04:55

Speaker 3

Over the course of my young, the ten years I was in primary school while I was in New York is really when there was a mass exodus of manufacturing from upstate. So it left the United States, it left the rust belt, if you will, and went to Mexico, China went south. And so what I saw, they had a huge impression on me. What I saw was a lot of Americans losing really good paying middle class and upper middle class jobs. And when I went to college, I wasn’t really thinking about that. When I went to college, I initially studied sociology and history in the going to teach. And I learned. While I was studying sociology, I took a couple of courses on sociology and the economy and sociology and employment.

05:47

Speaker 3

One of the things I learned in those courses was that manufacturing left the United States not because corporations were greedy, that’s what I had been taught in the. But that it was just corporate greed. They wanted to fatten their wallet. No, the reason they left was because they could no longer compete in a global economy. And the reason they couldn’t compete was because they didn’t leverage technology to innovate. Now, there are a whole host of reasons why that happened. While I was in college, I started learning about, hey, man, that was avoidable. Watching my friend’s parents go from making really good job, really good money, to working at gas stations, losing their homes, going back to work on farms, that left an indelible impression on me. And when I was in college, I learned that it was avoidable.

06:42

Speaker 3

So after I graduated with my initial undergraduate degrees, I got a job, just by blind luck, working in the industry, mining industry, in 2000. So I got a job working in a salt mine as a laborer while I was getting ready to go to graduate school. And that was when I was first introduced to industrial automation. So the story of how I got introduced is kind of funny. While I was initially in college, I put myself through school. I worked in an arcade, and I got a certification in five volt DC systems while I was there so that I could maintain ping pong or pinball machines. I mean, that’s literally, I went and did a two month course so I could maintain pinball machines.

07:28

Speaker 3

And so when I fast forwarded ten years to working in a mine, one of the things that I had learned how to do when I learned DC systems was how to read IEC drawings. We had some mining equipment that was built in Germany, and it was all Plc operated. No one in the mine really knew how to work on plcs in general. Automation really hadn’t taken off in mining. And my supervisor said to me, hey, can you read this drawing? I mean, I’m a laborer. I’m a guy shoveling belts. And he saw my resume. He saw that I could read IEC drawings, and he said, can you read this? And I said, yes. And he said, I’m going to send you with an electrician, and I want you to read this drawing for this electrician. And I said, okay.

08:15

Speaker 3

It was all written in German, and I do speak some German. So I went with him, and I worked with this electrician, this guy who knows nothing about three phase electricity. I know nothing about automation or plcs or instrumentation. I know nothing. I’m working on a roof bolter that was supposed to be automated. You’re supposed to push a start button and it drills a hole in the roof and then puts a bolt in there and torques it down to 900 psi. And I’m working with this guy for the last year, it hasn’t operated. Everybody in the mine tried to fix it. It just sat in an old area of the mine, but it was a half million dollar machine that they wanted to run. And he and I worked on it.

09:00

Speaker 3

The first day together, he got frustrated and left and it was just me there. So the second day I just started trying to troubleshoot it. And I literally learned on in like one day I learned how to troubleshoot this piece of equipment. And there are people I worked with in this mine who will listen to this podcast and they’re going to be nodding their head yes and laughing about this story because it became sort of legendary within the company that I worked in. On day three, I solved the problem. It was a simple short in a piece of conduit. I pushed start and the machine ran. And from that moment on, I became the smag guru and this guy who knows nothing about three phase nothing.

09:39

Speaker 3

So at the same time, I’m starting my graduate work in education, I’m getting a master’s degree in education, and I get introduced to automation. And now if you couple that, so I’ve got automation, that technology that we didn’t use in the manufacturers, do more with less. That had a direct impact on the people I grew up with. And then when I was in college in the learned what it is they could have done to stem the tide. And now, just as 2000 is coming into play, the aughts, it all gets put together. I have an opportunity to leverage the technology they could have used to do more with less. And now I get introduced to the technology and the light bulb comes on for me.

10:31

Speaker 3

So I decide, okay, I’m going to become an engineer, electrical engineer, and what I’m going to do is learn everything about manufacturing that I can, and then I’m going to teach manufacturers how to keep jobs in the United States. And that happened in 2000. And so the course of my career was I spent five years in mining while I got a degree in electrical engineering and completed my master’s degree in education. Then I moved to the printing industry, and I worked for two years in the printing industry, learning profibus, profinet high speed dirty process on printing machines with motion control. And then I moved to the steel industry so that I could learn heavy industry batch processes in making billets. And then the rolling mill process with high speed motion with distributed control systems, DCS systems.

11:23

Speaker 3

And then I moved to tier one automotive to kind of bring it all together. And I spent two years in tier one automotive. And then once I felt like I had the education, and now I had the experience that I needed to go and help other manufacturers change the way they do business. In 2011, 1011 is when I moved to systems integration. And so the last 910 years, I have been basically taking everything I learned, the anecdotal stuff I learned in the kid, the education I acquired in the 2000. Manufacturers do more with less. And it’s been my mission since 2000. So that’s how I got to where I am today.

12:11

Speaker 1

I love that. I love the shaping of the different influences in the different industries. And I think part of what, if you listen to any of walkers, to our listeners, if you listen to any of walkers or watch any of the videos, I think being an online educator and your passion for teaching definitely comes through. And that’s what first attracted us to sort of join your community and just follow that. It’s a fantastic story. And I love the fact how you also reacted to the circumstances and to what has happened to you in your life. I think very often there’s an old saying that says the 10% of your world is what happens to you and 90% of it is how you react to it. And I think your story is one of resilience and one that definitely speaks to that. Thank you.

13:00

Speaker 1

And I love that. Well done on that. Obviously, today you’re a very successful person, and that success has allowed you to be, again, not only a good educator, but also just a good influence to the community as a whole. So well done, Walker.

13:14

Speaker 3

Thank you very much.

13:17

Speaker 1

I wanted to quickly ask you about the, you mentioned the very expensive mining equipment. So the mining industry in South Africa has obviously been the stronghold, really, of our economy and the manufacturing world. And I think very often, and maybe we can chat about a little bit later when we get to that state, but I think very often the very expensive equipment you spoke about, we often see that it’s very capex heavy equipment and investment. It’s typically made to run forever, and it’s typically not made to be online. And I’d love to get your. I’m so happy that you had the mining industry experience and background. I wasn’t aware of that, because that’s typically where we see these big, massive investments into these systems and machinery that’s made to run forever and not made to be connected to anything else.

14:04

Speaker 1

I’d like to chat about that a little bit more. I’m not sure where we’re going to fit that in.

14:10

Speaker 3

What I’d like to do is say this one piece. Part of what I learned during my mining experience. So I worked in a salt mine a half mile underground, underneath the lake, right? So I worked in a salt mine half mile underground. It was a seven minute elevator ride to the bottom. It was 72 degrees Fahrenheit year round down there. Very dry, humidity. And the mine was about 6 miles from the bottom of the shaft out to the furthest point. What people don’t understand is that in mining, it’s a whole different world down there. The regulations are different. You’re governed by a completely different regulatory body. Everything you need. It’s like being on another planet. Everything you need. There’s no natural resources. Everything has to be brought in or shipped out, including the mining equipment, which comes down in pieces, by the way.

15:07

Speaker 3

Most people don’t know that they cut it apart. They cut it into little pieces and bring it under and gets reassembled. Part of what I learned in mining is that once the equipment is there and once it’s working, they don’t do anything to it. All they do is maintain it. There’s no such thing as innovating the equipment. They don’t do that. They don’t plug it into an ecosystem. They don’t even think about how they can collect data off of it and learn how to improve their process. That’s not the way it works. It’s a completely different mindset. And so part of what we’re trying to do is we’re trying to educate executives across all sorts of industries about the questions they should be asking of their oems before they get the piece of equipment underground.

15:56

Speaker 3

So, if we’re talking about mining, what questions should you be asking? Caterpillar or Elphinstone? So, Elphinstone is a partner of Caterpillar that makes basically front end loaders for their really squatted down, really short front end loaders that scoop up whatever you’re mining, right?

16:17

Speaker 1

Yeah.

16:19

Speaker 3

If the manufacturer or if the customer, if the miner was asking Caterpillar and Elphinstone or Fletcher or smag in Germany to ship their equipment IIot ready, and they were able to give it. They were giving them specifications. Okay, we need you to support. The hardware you use has got to support these protocols. It’s got to be report by exception. It’s got to have wireless technology. We got to be able to connect it into this ecosystem. If the miner gave that specification to the OEM would support it. The reason it’s not supported is because the question isn’t being asked by manufacturers and by heavy industry. And the reason it’s not being asked is because there’s too much confusion in the space as to what industry 40 is. Digital transformation. They don’t even know how to quantify it themselves.

17:10

Speaker 3

So that’s part of the reason we spend, I’ve spent more than a quarter million dollars of my own money educating the market for no return. It’s not like this is a business development tool. It’s really, hey, this is what we’re going to invest in the community. And the reason we’re going to make that investment is because we have to eliminate a lot of this disinformation. And if we can do that, if we can educate the community as to what digital transformation actually is, what industry 4.0 actually is, and more importantly, what it isn’t, then those smart people who are listening to you can connect the dots and they’ll start asking their oems to send their equipment IIot ready. As it stands right now, oems will develop solutions that they call iiot ready, that are not iiot ready.

18:03

Speaker 3

But the consumer has no idea the difference. They have no idea. There’s no regulatory body that’s telling them they can’t do it, they can’t ship it that way. It’s just false advertising.

18:16

Speaker 1

Even just around the protocols, what’s available protocol wise? Sort of, is it open, is it proprietary? And really the link that I’m trying to make between the equipment is with the advent of sort of cheap networks and cheap devices, there is a view, and I mean, we’ve heard a lot about digital transformation. There is a view that there’s a lot of velocity, a lot of traction behind it. Have you seen, in terms of digital factories or digital manufacturing, what does it look like over the last couple of years? Are we heading towards that in a good steady pace, or is it still, to your point, too much confusion there to make real traction and real progress?

18:55

Speaker 3

No, we are definitely heading there at a steady pace. Here’s the caveat, okay? And this is the one thing that most people just don’t think about. When I talk to people about digital transformation industry 40, there are really three verticals I talk about. So the first thing is I try to define what the important concepts of digital transformation are. Now, whether this is a manufacturer, whether this is an integrator, whether it’s an OEM. I talk about three important concepts, right? These concepts, these definitions are incredibly important. They are the prerequisites for successful digital transformation. So number one, the first and most important concept, digital transformation is a strategy. It’s not a project. So it’s a mindset. It’s a strategy of the way you’re going to on how you’re going to connect your business. It is not a turnkey project.

19:58

Speaker 3

It’s not like writing an RFQ and having somebody come in and put in an MES system with ten specific capabilities and you can write a functional acceptance test at the end to deliver, to say, yes, all ten of those capabilities are there. That’s not digital transformation. Digital transformation is a strategy. It’s an overall vision for the business. I use Amazon, the email that Jeff Bezos sent in 2003 to his entire company. At 03:00 in the morning, he sent out an email saying, this is stupid, that we share data with each other through departments, in spreadsheets and via email. So from this day forward, our strategy is going to be that you will build software APIs to communicate with one another, and you will expose all pertinent data and information to all other departments. That will be your strategy.

20:49

Speaker 3

And if you don’t do this, you’ll be fired. That’s literally what he wrote in the email. I mean, that’s not verbatim, and I can share the email with you. It’s a strategy. Amazon implemented a strategy for digitally interconnecting their entire business. That was their strategy. Number two, digital transformation is about transforming the way manufacturers operate their businesses. Not operate their processes, but how they operate their businesses, by leveraging data they generate every day, but they never or rarely consume in real time. Number three, when it comes to digital transformation, and this goes directly to your question, Giaco, not everyone can be helped. So if you are someone who can help an organization digitally transform, the first question you have to get answered is, can these people be helped? Can they get out of their own way? Not everyone can be helped.

21:46

Speaker 3

Companies are going to go bankrupt. Companies have poor leadership, companies have lack of vision. Companies don’t have the capital. Invest your energy in the businesses you can help. Start with finding people who admit they have a problem. You want to talk about the companies that successfully digitally transform. They know they have a problem and they can be helped. They understand that digital transformation is a strategy, it’s not a project. And they understand they’re going to be transforming the way they operate their business. They’re not implementing another piece of software that’s going to give them another piece of data that they can’t see in.

22:26

Speaker 1

Real time just for the sake of doing it. Yeah, we spoke about it before. The call is finding thirsty horses and not forcing horse strategy if they’re not ready.

22:34

Speaker 3

Which is why I got excited. Which is why I got excited when you said the. Because it means you get it. You understand it. By the way, in our industry, guys, you know just as well as I do that our contemporaries, right, we’re colleagues, right? Intellik integration, element eight. We do the same things.

22:52

Speaker 1

Right? Yes.

22:53

Speaker 3

Not everyone in our industry gets it. And all you have to do is go to the CSIA conference, which I know Lenny attends each year. All you’ve got to do is go to the CSIA conference to see that most people don’t get it. In our industry, 70, 80% don’t get it. Definitely.

23:09

Speaker 2

Walker, what you’re saying is it’s very true. It’s also something that I think people also get the confusion between digital transformation and digitization. Digital transformation is definitely not something that you can go to the shop and buy off the shelf. Right. And I think there’s a lot of confusion about, oh, it’s just a new software package. Oh, it’s just this new instrument. Oh, it’s just something that’s got the label slapped onto it, that it can connect. And I’m glad you brought it up, that it’s a strategy. And that strategy doesn’t sit with, I mean, there’s even new titles now for people and organizations that needs to look after digital transformation. CDos, or whatever you want to call them, doesn’t sit with them. It actually sits with the guy right at the top.

23:49

Speaker 2

He needs to drive that strategy, and he needs to make sure that everybody’s aligned on that strategy.

23:55

Speaker 3

Yeah, that’s absolutely spot on what you said, lenny. Absolutely spot on. And here’s the irony. Those chief digital officers, right, those chief digital officers we talk about, they’re hiring people like us, people like you, to teach them how to do it. And when you don’t know how to achieve this transformation of your overall business strategy and the way you operate, you are susceptible to being hoodwinked. You are susceptible to a really great salesperson convincing you to buy a product that can’t help you.

24:32

Speaker 1

Yeah.

24:35

Speaker 3

A couple of other things I just want to talk on real quick, some important definitions that I kind of want to lay down industry 30. Most people hear, we hear, industry 30, stop making it so complicated. Industry 30 is the automation of manufacturing, and it created data. That’s all it did. Industry 40 is the digital integration and automation of business processes. That is, it creates information. So the industry 40 is all about creating information from all the data that you created. With industry 30, digital transformation is nothing more than going from manual or paper processes to integrated digital processes. And by a function of doing that, you have transformed the way you do business. That’s really what it is. And IIoT is the ecosystem we create by digitally transforming.

25:29

Speaker 3

So the industrial Internet of things are all the nodes that are connected together that help us create that digital information from that discrete digital data. And then to be successful, you asked the question, do we see successful digital transformation initiatives? Yes, we have many of them. There’s also lots of failures. In fact, we talk about this all the time. When everyone started putting in digital SCADA systems, replacing their push buttons and pilot lights with wonderware in touch, in the huge movement, right, the success rate was like 90%, 95%. It was easy to do that. There’s nothing special about building a SCADA system, right. The problem is that once we move to, like MEs, which manufacturing execution was really that first step in digital transformation, we’re going to get to that in a second, actually.

26:30

Speaker 3

I guess we see a high failure rate of MES implementations. Let’s say maybe you have a 60% to 70% success rate with manufacturing execution. And when it comes to digital transformation, we’re seeing like ten to 20% success rate. 70, 80% of businesses who are trying to digitally transform fail the first time. And the reason they’re failing is because their mindset, they don’t understand it’s a strategy, not a project. So some important concepts. So say you’re an integrator, or you’re an Oem, you’re a software developer, you’re a manufacturer. What are the things in order for me to keep my eye on the ball for digital transformation, what do I need to do? Well, number one, you need to know what your digital strategy is as an organization.

27:16

Speaker 3

And that goes right to Lenny’s point, that the guy at the top’s got to know what his digital strategy, so. Or the guy or gal at the top’s got to know what his or her digital strategy is. If you don’t know, stop it. Stop what you’re doing, take three steps back, call a meeting, and find out what the digital strategy is. If you don’t have a digital strategy start there.

27:41

Speaker 1

Number two, where does the business case come into that?

27:46

Speaker 3

The business case for digital transformation?

27:49

Speaker 1

Yeah. So often when we talk about digital transformation and sort of strategies and tactics to achieve whatever level of sort of next integration we’re looking for, it’s always attached to some form of business case to serve a business need, whether it’s improved customer satisfaction, just improved bottom line. But some of the conversations we’ve had over the past couple of episodes with a couple of folks, they said that very often they’ve seen those fail because there isn’t actually a business case defined to doing this. It’s simply a case of, well, let’s do this.

28:22

Speaker 2

Because everybody else is doing it.

28:23

Speaker 1

Because everybody else is doing it.

28:27

Speaker 3

Here’s how I answer that question. By the way, the chief financial officer, when I’m in front of the board, the chief financial officer is the one that asks that question. They’re generally the one that says, give me the business case, what’s the ROI? And so I don’t answer that question with answer. I answer that question with a question and I say, Mr. Chief financial officer, before Apple came out with the iPhone and Steve Jobs spent nearly a billion dollars in development on the initial iPhone. Tell me what his business case was. And there’s no answer. The chief financial officer can’t tell me what the business case was in 2005 and in 2006, when Apple was developing the first iPhone.

29:20

Speaker 3

And I say to him, is there any question that the iPhone saves you or that your smartphone saves you time and it saves you money and it makes you more efficient? And they’ll say, yes. As long as I say, off social media, they’ll make jokes about that, right?

29:38

Speaker 1

Social dilemma. Correct.

29:40

Speaker 3

There’s no question, it’s self evident that connecting, being connected to all of the nodes in your life makes you more efficient, right? That’s what digital transformation is. I hold up my smartphone and I say, this is all of human knowledge. This is everything you need to know about your life. This is the location of every member of your family. This is your access to your net worth. This is everything, right? Humans are all Androids. I say that and I go, what digital transformation is creating the smartphone for a smart factory. That’s digital transformation. So you make the business case however you want. But if what you do is ask your digital transformation team, who needs to be remained agile in order to solve problems, to make the business case first, then you’re never going to get your feet off the ground.

30:39

Speaker 3

That’s how I answer that question. Now, I know that’s a non answer. It’s a non answer to your direct question, but it’s much more effective than trying to answer that question directly, 100%.

30:51

Speaker 1

Yeah, it’s a good analogy. I like that as well.

30:55

Speaker 2

I think to the point that you mentioned of Steve Bezos email, if I open up my phone, everything I’ve got on there, I have access to. So why are we still in this mode of not having everybody in our organization? Everybody’s got some form of way to influence what we’re doing at the end of the day, but we’re still stuck in this rut of not giving the information to everybody. It doesn’t matter if it’s the bottom line numbers or what our current throughput or output is. It’s almost like there’s still these people that hold onto this information for maybe it’s their own benefit, job security, I don’t know, but it’s definitely not the way to drive a business forward.

31:34

Speaker 1

Well, sometimes the information exposing the truth behind the facts behind the information, sometimes exposing that truth, a lot of times, people don’t want to see that because they want to manipulate that data.

31:44

Speaker 3

Well, Lenny, let me ask you this, Len, when you implement an MES system, you’re an MES guy, right? So you’ve had plenty of help, especially with flow software, right, being able to calculate Oee. Everyone calculates Oee on some level, right? They’re either doing it in an excel spreadsheet. Someone somewhere is calculating capacity and efficiency in every organization, whether they’re doing it digitally or not. That’s up to them. What you do. What you do, and what I have done is we build digital mes systems that calculate actual overall equipment effectiveness against the actual theoretical rate of specific equipment cells and processes.

32:29

Speaker 1

Great.

32:29

Speaker 3

So the number we give them is the real number. And how do they normally react the first time they see the real number, in spite of the fact that they’ve been calculating a number for many years?

32:43

Speaker 2

Oh, that can’t be right.

32:45

Speaker 3

That can’t be right. That’s the first thing they say. That number can’t be right. It’s a window into their thinking. If the way they react to that is there’s got to be something wrong with the way you’re calculating it. And we’ll go ahead and show them every individual transition, every count, here’s every state change. Here’s your theoretical rate. Here’s the math. We’ll draw it on the board. The way our software is calculating it. Is the way I just did it here on the board. If their answer, even after that conversation, it is, you’re still wrong. Then they can’t be helped. You got to go find somebody else in the organization, or you got to drop those guys. It’s the same thing with digital transformation. Not everyone is prepared to hear the truth.

33:33

Speaker 3

Let’s say the person in charge is someone who’s 60 years old and they’re a couple of years away from retirement, and as long as their pension isn’t compromised, we have to ask these questions. Do they really care whether the company is stable for the next 50 years or next 100 years? Our motivations are different. So we have to honestly ask the question, what are our motivations? Jacob, let me talk about this. This is the reason we talk about our core values all the time as an organization. In fact, the very first thing I ever say, john McLeod, who’s on here, our chief experience officer, and he’s been our business development guy for years. He’s built our business development group. He’s heard me say this thousands of times in thousands of meetings.

34:20

Speaker 3

And the first thing I say is, you guys have to understand that working with us is not like working with other companies. We have five core values, and we live by them. The core value, number one, is transparency. We share all information with our entire organization. Number one, we expect you to do the same thing. The only thing that we don’t share with our employees are the things we’re legally not allowed to. One of the first things our employees say is, I can’t believe you guys share the information you do with us. Transparency is the hardest part. Not every organization is prepared to be transparent. Lenny, I’m with you 100%. I don’t understand why manufacturers treat data on a need to know basis. It’s competition. But what it does indicate, it’s competition. It’s a lots of things, right? Lack of faith.

35:14

Speaker 3

They don’t want to expose the truth. They’re afraid of labor movements, whatever it is. My philosophy is you can’t go wrong by sharing information with everyone in the organization, because what you’ve done is created. You’ve basically presented the problems the organization faces with every person on the team. And now you can collaborate on your solutions, which is what you’re really doing, right? So, number one, it’s Transparency. Number two, it’s authenticity. We don’t expect our employees to be people they are not. So if you think that I’m being a jerk, tell me I’m being a jerk. If you are a jerk, be a jerk. We don’t care. What we care is that you’re right. Organizations need to take that approach. They have to care about fidelity of data and they have to care about the reliability and accuracy of information.

36:07

Speaker 3

And if those are not priorities for those organizations, then of course you’re going to fail. When it comes to digital transformation, of course you’re going to fail if what you say is, I want to digitally transform. But then in the following statement you say, but I don’t want you to have access to all the data. I don’t want you to connect all the data to everything, and I certainly don’t want you to present the information to all consumers. Well, then you’ve made the decision to fail when it comes to digital transformation, not me. Right? You’re not ready. A couple of other things real quick. I want to go on about digital transformation because there are people on this who are listening to the podcast who want to know how to be successful. How can I successfully digitally transform?

36:49

Speaker 3

So number one, know what your digital strategy is. Number two, you need to approach every project as one part of a bigger whole. How does what I’m doing right now fit into the digital strategy? And how will the next project that we work on be built on top of what I just did? Number three, make no assumptions about how data or information will be consumed. So when we build dashboards, we make assumptions about how that will be consumed. Stop doing that. You build frameworks, we build technology stacks. We create the infrastructure and then let them decide what they want to consume and how they want to consume it. Number four, treat all producers and consumers of data as a node in an ecosystem. Number five, and this goes to Lenny and our guys, right? Build a technology stack.

37:38

Speaker 3

Do not build a software or solution stack. So don’t go buy Rockwell’s connected enterprise. That is a solution centered approach. Right. Build a technology stack. That is, we are going to build an infrastructure that is built on top of MQTT or DMP three or AMQ or whatever. We’re going to build a technology stack and then we’re going to give all of the departments in our organization minimum technical requirements that any solution they want to use has to meet.

38:12

Speaker 1

Right.

38:12

Speaker 3

And number six, remain agile. You need to expect that goals and expectations are going to change as your knowledge evolves. Digital transformation creates new knowledge and you have to be able to adjust to people’s changing requests based on the knowledge they are acquiring by the solutions you are giving them while you’re digitally transforming.

38:42

Speaker 2

Yeah, Walker, very important there, I think on the technology stack mean we’ve seen so many solutions. As your point earlier into the podcast you get this very clever sales guy that if you’re not informed, you’re going to fall into his trap. Right. And you’re going to buy something that, oh, you want that piece of data out of it? Well, it’s going to be this extra this and this extra that. By using open standard technology that’s available in your stack, you make sure that thing is future proof and that it is available to connect to whatever is in the future or that legacy stuff that you’ve got. So I really like that analogy to stop thinking about a solution stack, start thinking about the tech that you need to have to enable the strategy.

39:25

Speaker 3

Exactly.

39:27

Speaker 1

Yeah, I really like that. Very practical steps. I think it was five or six of them like that. I quickly want to ask you mentioned in the last couple of minutes, you mentioned human a whole bunch of times, which I love because I mean, this is ultimately about the humans. The tech is there just to enable and to empower. It’s all about humans and human innovation. When it comes to human change management, what are some of your observations and experience around people’s? Not only, I suppose, if it’s aligned with the strategy and the values, not really their want to transform, but also their willingness to be open to it. And very often the tech and everything else that fits around it just doesn’t suit a couple of individuals. Or let’s rather say that the body rejects the organ.

40:17

Speaker 1

Just in terms of human change management. Is there a specific strategy for that as well? To get folks on board and to get people behind the strategy easier and less opposed to dealing with new tech and using new tech.

40:32

Speaker 3

Absolutely. So it’s a very common question. It’s a great question. All right, so this is where it gets a little more complicated. Okay, so there are really two approaches to the human change management. Right. One of the reasons were talking earlier about, I have a reputation that I can be a jerk or that I can be an ahole, that I’ll say things other people won’t say, or I might run through an obstruction, a barrier that’s in front of me, I won’t handle it softly. I might take the bull on a china closet poach. Right. And so the reason I do that is because I want to see a measurable change in manufacturing in the United States, specifically during my want, before I die, I want to know that I made a measurable impact.

41:29

Speaker 1

Right.

41:30

Speaker 3

And so in order to do that, we really can’t wait. We can’t wait for in generations of engineers and generations of operators and generations of managers to retire and get replaced by people who grew up with technology in their hand.

41:45

Speaker 1

Right?

41:45

Speaker 3

We can’t do that. So what we have to do is we have to assess every person we come in contact with as to where they fall on the scale, right? So on the far left of the scale, you’ve got the progressive thinker, the person who’s never satisfied, no matter what. They’re always tinkering with the latest technology. They’re always operating on the bleeding edge. They’re always building proof of concepts and prototypes, but they never get anything into production. And on the far right, you’ve got the person who masters the existing technology. They leverage Kaizen and continuous improvement to continuously make the technology that we have today more perfect. But what’s important to note about them is they never introduce new technology, ever. So that’s what you got on the far right. What you’re looking for are the people who are center left, right.

42:45

Speaker 3

You need people on the whole scale. You need the voices on the far right to make the case for why we shouldn’t be reckless introducing new technology. And you need people open minded on the far left who are going to say, hey, there’s this great new technology that just came out that we should start playing with. And you need a whole host of people in the middle. But there’s really two approaches to successfully digitally transforming. You have to successfully convince the person who’s on the far right that in this case, it’s time to introduce new technology. And if you don’t do that, you’re either going to fail or you’re going to be forced to let them go. Now, I will say that again, the caveman, the citizen, against virtually everything that we all run into.

43:31

Speaker 3

You, as the champion of digital transformation have either got to convince that person that this is the one time you should embrace change, or you got to let them go. And companies hire me. Hire me to do the dirty work. There are many large organizations, if you look at our client list, there are many large organizations who have hired me to come in and identify who’s going to come along and who won’t and give them the list of people that they’ve either got to reappropriate the different positions or leave the organization altogether. Now, to answer your question, I can understand why it’s the harsh reality. Yes, but I want to follow up on the answer. The other approach, how do you get that guy on the far right to embrace change. This one time you craft the solution in a language he speaks.

44:35

Speaker 3

So he or she speaks. Here’s a question I ask all the time, and I encourage you guys to use it. I will go into a room and I will say, by the end of this meeting, I’m going to ask every person in this room to tell me a problem they’ve been trying to solve for a week, a month, a year, ten years that they have yet to find a solution for. And it can be anything. It doesn’t have to be automation related. It could be anything. Any problem you are trying to solve that you can’t find a solution for yet. And I’ll say, I want you to be thinking about that.

45:10

Speaker 3

And then we’ll go and we’ll do our presentation, and it’s always organic, and we whiteboard, and we ask questions related to the industry workflow and tell us what CRM you’re using and how do you convert a sale into resource planning, all that kind of stuff. And then at the end of that meeting, we will go around the room and ask every person, guys, remember that question we asked. Tell me the problem you’ve been trying to solve. And we go around the room and everybody answers a question, we write them down, and then we pick the hardest one. We pick the one that we think no one thinks that we’ll ever be able to have a solution for. And then we solve their problem in 10 minutes. Most of the time we do it in ignition.

45:50

Speaker 3

Most of the time we will literally sit down, we’ll put ignition up on an overhead board, and I will solve that person’s problem in 10 minutes. And hopefully it’s a problem they’ve been trying to solve for ten years. And if we do that, what we’ve done is we’ve convinced every single person in the room that they’ve fallen behind the times.

46:08

Speaker 1

Yeah.

46:10

Speaker 3

And that’s the approach. It’s never good to take the while I have a reputation of being a jerk and rough around the edges, I never go into a room and go, you’re an idiot. I never do that. I never go in and say, I use soft skills as long as they’re going to be effective. And that is the most effective way to manage change in human beings. Because there’s no rebuttal for solving a problem that you’ve had for ten years.

46:38

Speaker 1

Yeah, I mean, super. Victor, I like the other thing that you mentioned. I think it definitely does tie back with values, the kind of folks that you want working with you within your business and part of your team values is really where it starts, because those values typically drive the behavior, the actions, and probably most importantly, the habits for all of us. And that’s why those values, and very often that kind of an individual, they also wouldn’t live the kind of values that your brand and your business aspire to. And that’s another good reason. If they’re not willing to adapt and adopt some of those values, it’s just another reason to maybe part ways.

47:25

Speaker 3

Absolutely.

47:26

Speaker 2

Walker, why would you think it takes people ten years to solve a problem? Is it the way that we stuck in thinking of integration? Is it a way of just not being educated enough on what’s available or that’s been changed in the past ten years? But as you mentioned, you can normally solve a problem for them in 10 minutes. So it’s obviously the tech is there. Right. Why do you think it took them ten years to get to that point?

47:54

Speaker 3

Well, now, this is where my sociology background and my wife has a degree in psychology, and my mother in law is a psychologist. So this is where.

48:08

Speaker 1

That.

48:11

Speaker 3

Is where my liberal arts background comes in. So one of the things that I am good at is I’m very good at reading people. And most people on my team will tell you that it’s really creepy. I’m very good at breaking people down quickly, and one of the things that I’m trying to identify when I meet anyone is I’m trying to identify, are you a person who believes every problem has a solution? I’m trying to determine that.

48:38

Speaker 1

Right.

48:39

Speaker 3

So, Lenny, what I know about you, and we’ve never had this conversation, but I know that you believe, without a doubt, that 100% that every problem can be solved leveraging technology somehow. Right. You don’t believe you are a guy who runs into the fire when everyone else is running away. You believe that it’s possible to snatch victory from the jaws of defeat in every situation.

49:01

Speaker 1

Right?

49:02

Speaker 2

Correct.

49:03

Speaker 3

Not everyone is like that. So if you’re the person who has a problem and you believe that there are unsolvable problems, or you believe that solving this problem will create or attempting to solve this problem will put me at risk if I fail, then you may decide that inaction is the optimal decision in this case.

49:29

Speaker 1

Right.

49:29

Speaker 3

So what we try to do is this is where we talk about agility and creating teams, right? This is why we talk about the core values of transparency and authenticity and expertise. So one of our core values is expertise and humility. Two of them. Expertise, is we’re the expert and we act like it. That is we’re an expert in something. Every person in our organization is an expert in something. You better know what you’re an expert in. But humility is the idea that we’re not experts in everything, and we’re okay with admitting that. We encourage that. You admit you don’t know something. I’m not the person to solve this problem. And humility is about going and getting people who can solve the problem for you. So to answer your question, Lenny, it’s human nature.

50:20

Speaker 3

It’s the construct of societies, of groups, of people, and it’s the thing that’s inside of each of our heads. And humans are diverse, and we’re versatile, and we can overcome challenges. But not every single person thinks in terms of, the goal is always to make the best mousetrap. Some people say sometimes it’s better to leave well enough alone. And that’s the reason that problem festered for ten years. It’s not because that person’s unqualified. It’s not because they’re not educated. It’s because they think differently. And that’s why we focus on trying to change the way people think.

51:03

Speaker 2

Cool, thanks, Walker.

51:04

Speaker 1

I like that. We just cautious of our time. There’s so many questions we want to go through. So we’ve spoken about the steps to digital transformation, important concepts, having a defined strategy. I think we’re actually thinking about this now, Lenny. We’ll share a couple of these points and sort of note format afterwards. So now we’re looking at, what do we call it? A future digital factory. Is that the best terminology? What does that typically look like?

51:33

Speaker 3

All right, so we call this the holy Grail. All right, so right now, we’ve been doing our mentorship program, where we’re essentially training engineers how to do what we do. So people have mentorship program.

51:48

Speaker 1

I saw that a couple of weeks ago. And, I mean, you’ve had the few iterations of that. That’s such an incredible.

51:55

Speaker 3

Yeah. So we have two programs. We have one called digital mastermind, which is. This is primarily, executives have joined this digital mastermind program. It ended up being an eight hour session, two four hour sessions. Our goal was for it to be one four hour session where we basically taught them, what’s the process of digital transformation? Right. And we get deep into the weeds with it. And then in mentorship, we talk about the professional development.

52:30

Speaker 1

We.

52:30

Speaker 3

They go through our. In a mentorship program, the engineers are going through the actual training that we put our engineers through.

52:37

Speaker 1

Excuse me.

52:38

Speaker 3

Sorry. So that’s in mentorship, but in both of those programs. One of the things that we talk about is, what is the goal you’re working towards?

52:47

Speaker 1

Right.

52:48

Speaker 3

And you call it a digital factory. What does the digital factory look like? We call it the Holy Grail. What is the future of manufacturing? And that holy Grail is this. It’s a fully integrated business made up of digital factories. Okay? Digital factories are everything, and everyone is plugged into the network. Say that again. Everything and everyone is plugged into the network. Right now, all over the globe, you have intelligence on the plant floor that’s plugged into nothing, and you have people who have no access to the smart stuff. So one of our goals is to get everything and everyone plugged into a network.

53:29

Speaker 2

Number two, we spoke about it.

53:30

Speaker 3

Yeah, go ahead.

53:31

Speaker 2

We spoke about it as well. Very mean. We’ve encountering this so many times on our manufacturing plant floors that the OEM is kind of holding you hostage for the data that sits on that device. That cannot be the reality anymore, correct?

53:50

Speaker 3

Number two, the layers of the business are integrated, and they operate based on data and information from all of the other layers in real time. So what are layers of business? You have the business layer, your CRM, the planning layer, your ERP, the manufacturing layer, the MES system and the SCADA system. Warehouse, management, shipping, et cetera. Those things are all connected. Arap. They are all integrated, and they all operate based on data and information from all of the other layers in real time, which. There are very few businesses that do this right now. There are a handful. Some of our clients. Tesla is a really good example. Amazon’s another really good example. There aren’t many that operate this way. And this is part of the holy grail.

54:38

Speaker 1

Right?

54:38

Speaker 3

Number three, stakeholders, all stakeholders in the organization know the state of the business in real time. That’s what a digital factory is. That’s what digital transformation is. Stakeholders know the future state of the business in real time. This is why I love flow software. Right. Lenny will tell you, the first time I looked at flow three years ago, I jumped out of the demo for two reasons. Two reasons only. Number one, flow made it very easy to calculate future state based on past performance in a single dashboard.

55:12

Speaker 1

Right.

55:12

Speaker 3

I could illustrate what your future state is going to be based on current state and past performance. Right. I got excited about that because that’s one of the building blocks of digital transformation. And number two, it’s the integration of social media. Right? Your flow software was the first software I ever saw with seamless integration with Slack. Right. The next one you leverage technology that is machine learning and artificial intelligence, plus the ecosystem, to collect and analyze data and information. Now, some of that collection, that analysis is automated, and some of it is human. But right now, in basically every business, it’s just human. And humans can only look at so many variables at any given time. They can only consume so many variables at any given time. Machine learning and artificial Intelligence can do it in real time.

56:08

Speaker 3

And here’s the difference I talk about all the time. I use the face ID on my iPhone to open my phone. And for those of you who don’t know about machine learning, it’s machine learning that is using. There’s a machine learning algorithm that is predicting whether or not the face that’s in that camera is my face, the original face. Right. You could have had face id before we had machine learning, but you would have had to have an army of people sitting at the other end, looking at the face and the camera and making a determination as to whether that’s the person who owns the phone.

56:45

Speaker 1

Right.

56:45

Speaker 3

That’s the difference between using humans to analyze data and using machine learning and artificial intelligence. And I use that analogy all the time. Which one do you think is more efficient? Which one do you think costs less money? Right. The next one. Machine learning predicts future outcomes. This is where machine and human will interface in the future. Machine learning predicts future outcomes based on past patterns and current state. Okay, so we look at what we’ve known historically about the business. We look at the current state, and we say, what does this current state tell us about where we’re likely to go? Because what we want to do is head off problems at the past. We want to be. We’ve been using these terms forever, proactive as opposed to reactive.

57:29

Speaker 1

Right.

57:29

Speaker 3

So in order for us to be proactive, we have to predict the outcome. Right, next one. Artificial intelligence, based on what machine learning predicts, will recommend operational adjustments to improve future outcomes. So that comes from software, and it may be a series of recommendations, possible recommendations. And then the human being, the stakeholder, will choose to execute or not execute that recommended adjustment. So this automation and digital transformation is not about replacing people. What it is about. It is about using software and machines to do what they can do in volume and asking people to do what they do best, which is execution.

58:12

Speaker 1

Absolutely.

58:14

Speaker 3

That’s the holy grail.

58:16

Speaker 1

Yeah, I like that. Make available more of their time to do things that are more important, ultimately.

58:21

Speaker 2

Absolutely.

58:22

Speaker 3

We call it reappropriation. In my experience, I’ve been doing this 20 years now, and in my experience, automation. There may be a person who sits at the end of a production line and kicks a box and flips it over when you could put a prox switch and a flipper there, right? We automate and that job is no longer needed. In my experience, they don’t eliminate that job and do nothing. What they do is they eliminate that job and they take the money they were investing there, and they put it into another job that they couldn’t fill because they didn’t have the money. And those positions are higher up on the stack. They are better paying jobs. They are professional positions. They’re safer positions. Everyone benefits through automation and digital transformation. And it’s important that people understand that.

59:16

Speaker 1

Definitely powerful. I like that. I think we’ve run out of time. I think we’ve just been an hour, actually. We still wanted to have a quick chat with you about the role of Oee. I mean, Oee is, again, another one of the concepts that’s been around for quite a while. Certainly nothing new. Maybe just a quick, if you still have a few minutes, just the role of Oee in all of this digital factory and why we still need to calculate it.

59:42

Speaker 3

So there are a lot of people who believe are asking the question, and I know why you’re asking it, because there are a lot of people now who are saying, well, if I’m going to digitally transform and kind of just display everything in real time, well, what’s the need of calculating Oee? And the answer is, Oee is the pivotal calculation. So what that shows, when someone asks that question, it shows their lack of understanding of how teep, the teep calculation and the overall equipment effectiveness calculation work together. And we won’t explain that here. We’ve shot videos to explain how that works. But here’s what’s important. You have to calculate OEE. And it’s not optional. If you’re going to digitally transform whether or not to calculate OEE and calculate teep is not, they are connected.

01:00:29

Speaker 3

You don’t get to decide not to calculate it, and here’s why. The OEE calculation, the teep calculation is the context. You’re taking data and turning it into information. It is the piece of contextual information that all other software in the business uses to determine whether or not an action needs to be taken. If you’re running at 90% teep and you’re running at 70% OEE and your target is 82% OEE, that is, I want to make sure that my downtime is above a certain percent. I’m running my machines at a certain rate and we’re producing high enough quality material. If I can look at that number is the gateway to whether or not action even needs to be taken. And whether you’re having human beings or whether you’re having software do to determine what operational changes, adjustments should happen.

01:01:30

Speaker 3

The first thing they got to know is whether or not they even need to look. And that’s what oee and teep give you. Oee and teep tell you how well you are running, how well you are producing relative to how good you can be running and you can be producing. And all questions of whether or not I need to make a change pivot around that data point. So you can’t make operational recommendations if you don’t know whether or not you’re first running well. And that’s the reason it’s not optional.

01:02:03

Speaker 2

Walker, I can fully sentiment that. I’ve heard so many stories about operational decisions around big investment, about, geez, if we just put in another line, maybe we’ll make our target then with companies, or let’s double up the amount of workers that we’ve got on a shift. Surely that must increase our number. And then you ask them, but what is that number? Where’s your OEE dashboard? And they don’t have that. So thanks a lot for just echoing that again. And I think sometimes people, I don’t want to say misguided, but they think, oh, digital transformation, obviously I’m going to have machine learning and AI. That’s going to spit out the answer for me. Why do I need oe? Because it’s going to tell me ramp up or ramp down or whatever the.

01:02:43

Speaker 3

Case is, machine learning and AI needs Oee in order to give you the accurate information that you’re asking them to do. They need that number? It’s a variable that they have to consume, correct?

01:03:00

Speaker 1

Yeah. Fantastic. All right, I think we walk. I know you have a hard stop. I think we have literally 2 minutes left. Lenny, anything else from your side?

01:03:10

Speaker 2

I wanted to talk a little bit more about the technology stack and about unified architectures, especially for integration, Walker, but.

01:03:17

Speaker 1

I think just the whole concept of unified.

01:03:21

Speaker 2

Yeah, I think that might be a topic for a second podcast. It feels to me like we should get you on.

01:03:29

Speaker 3

I’d be happy to do it. Happy to do it.

01:03:31

Speaker 1

Yeah. Walker, thank you so much for your time. Any closing thoughts from you before we kill it?

01:03:38

Speaker 3

Yeah, well, yeah, let me just say this. I met Lenny and Graham about three years ago. I think we’ve been working together, collaborating. You guys are guys who get it. Not everyone gets it, and it is refreshing. I really thank you for the opportunity to come on here. I’ve always enjoyed working with you guys. Not that we’ve ever worked on projects together or anything, but we’ve collaborated from a strategic, philosophical level many times over dinners and that kind of, you know, you guys get it. And it’s very encouraging to see you guys taking this step and sharing with the community. Which is why when Clarice asked, hey, would walker be interested in joining the podcast? The answer was obviously yes. Because this forum, this platform is important for really cutting through the noise. Because right now, the noise is the barrier to success.

01:04:47

Speaker 3

It is a barrier to success. And one of the first things we have to do is change the way people think and clarify what digital transformation and the digital factory actually is. And I want to thank you guys for making that effort. It’s a lot of work to do this stuff. I know it personally and I appreciate it.

01:05:08

Speaker 1

Yeah, awesome. Thank you very much for that compliment. I think just to echo what you say, we’re never the holder of all knowledge. We don’t pretend to be. We’re just trying to play a very small part in helping spread the message and demystifying some of those concepts and things. So thank you so much for your time and definitely feels like we need a follow up episode. We definitely want to share the details to your channel. I think you’ve got over 5000 subscribers now. It’s very obvious why, just the great work and education that you’re doing. So thanks again. We’re going to share those details with our listeners and yeah, just thank you very much for your time again.

01:05:50

Speaker 3

Thank you, Jocko. Appreciate guys.

01:05:53

Speaker 1

Cool, Lenny. So next episode, I forgot we also spoke with Kudzai, just a young engineer in South Africa also doing some incredible online educating work with these little tutorials that he creates around connecting quickly and easily. We did record an episode with Kudzai’s Wayne again, so that’s coming up. We’re also chatting in maybe not next episode, maybe the following one. We’re chatting about cybersecurity in the OT space. We’re lining up some folks there to chat about the importance and the drive around some of cybersecurity and the importance. Especially with the advent of Internet of things and the open protocols. What else are we missing? What’s coming up next?

01:06:33

Speaker 2

I think it’s pretty much perfect timing as a thunderstorm is heading up here in Joburg. So it was great timing there. I just want to say thanks to Walker again, the education and the whiteboard stuff that he does put out from an education perspective. Again, guys, this is stuff that they are sharing, especially with Kutsai as well with industry 40 tv. It’s stuff that they’re doing their own free passion and will to educate us as a community. And again, thanks to these guys, the word is getting out. And really, I’m very positive and excited about digital transformation and trying to get more of these projects off the ground to succeed. And hopefully, guys that’s listening really take Walker’s advice to heart, how to start this journey, but let’s get it started.