Watercare Innovations is a leader in industrial water treatment solutions with a focus on Africa and the US. They boast over 40 years of experience in the industry, building a solid reputation for their customer-focused approach and commitment to leading-edge technology. Watercare doesn’t just provide equipment; they offer a comprehensive suite of services including process technology expertise, water treatment chemicals, and ongoing system oversight through remote monitoring. Their engineered plants cater to a diverse range of needs, from providing potable water and treating wastewater to recovering valuable metals and minerals from industrial processes.

The Problem

The primary challenge faced was the need for a comprehensive system that could prioritise live monitoring while incorporating control, trending, and ultimately prediction capabilities for a complex network of treatment sites.

The requirements specified the necessity for a solution that was compatible with open-source technologies, extendable, capable of handling unlimited tags, Linux-based, and backed by a strong community support system. Moreover, there was a critical demand for an improved data management system that could accommodate manual data inputs efficiently.

The overarching goal was to create a more interconnected and intelligent system that facilitated better decision-making and operational efficiency, moving away from isolated and manual processes to a centralised, automated, and data-driven approach.

The Solution

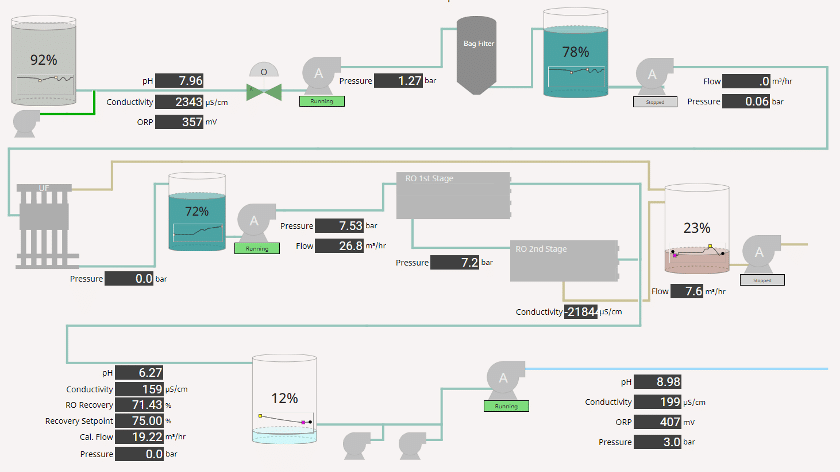

The solution to these multifaceted challenges was the development and implementation of a cloud application that could seamlessly control 12 treatment sites. This application was designed to manage over 28,000 tags and incorporate more than 1,500 manual data capture systems, demonstrating a level of scalability and flexibility suited to the complex needs of the project.

By connecting to 25 databases and driving six key projects, the application served as a centralised platform that was not only capable of live monitoring but also provided comprehensive control and data analysis features.

This solution was particularly tailored to meet the open-source compatibility, extendability, and Linux-based requirements, with an emphasis on community-driven development to ensure a robust and adaptable system.

- Cloud application controls 12 treatment sites

- > 28000 tags

- > 1500 manual data capture systems Future

- 25 Connected Databases

- Six key projects

value & Results

The implementation of the cloud application yielded significant value across various dimensions of the treatment facilities’ operations. It introduced scalable tag management and a robust, customisable historian with RO normalisation, demonstrating the utility of templating and User-Defined Types (UDTs) in achieving an efficient and streamlined data management process.

By centralising what would otherwise be a markedly disconnected set of services, the control room gained unparalleled oversight of operations, facilitating remote diagnostics by engineers and eliminating the necessity for on-site troubleshooting in many instances. This transformation not only centralised the management of Industrial Internet of Things (IIoT) and human-driven data but also set a foundation for future enhancements.

These enhancements include the integration of non-PLC systems, the utilisation of data mining and prediction for proactive maintenance and operations, and the development of a custom Laboratory Information Management System (LIMS) for automating lab activities along with live data referencing and validation efforts, thereby encapsulating a complete evolution towards an intelligent, data-driven operational paradigm.

- Scalable tag management

- Robust and customisable historian (RO normalisation)

- Templating and UDTs are critical

- Centralises what would otherwise be a very disconnected set of services

- The control room provides oversight of operations not possible

- Engineers can diagnose issues without necessarily being on-site

- Centralised management of data, be it IIoT or Human driven

Watch the full webinar on the Watercare Innovation story, click here to watch.