The manufacturing sector is a crucial enabler of our economic recovery and remains a focus for government and the industry. Moreover, as a nation, we have an incredible Southern African opportunity. This episode explores experiences, challenges and actions with Vinesh Maharaj, Associate Director and Smart Manufacturing Lead at PwC. We also touch on Smart Manufacturing concepts, technology innovation and the crucial role of people and creativity.

SPEAKERs

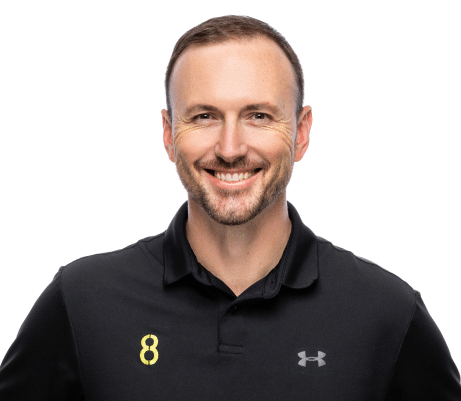

Smart Manufacturing Lead

Transcript

00:09

Speaker 1

Hello and welcome to the Human and Machine podcast. My name is Jaco, your host. As always, I’m back here with Lenny. Lenny, welcome back to the show.

00:15

Speaker 2

Yeah, I missed a few episodes. I think I was on leave one of them.

00:19

Speaker 1

I don’t know who approved that.

00:21

Speaker 2

Maybe the guy sitting next to me. But anyway, glad to be back. Jaco, joining you for I think episode number 25.

00:28

Speaker 1

Episode 25. If you missed last week we spoke with Devendry. Ankia Devendri is an engineer, but not first and foremost. She’s also a mom and a wife. And we spoke a little bit with Devendry about not only her high paced career and job, but also just a progression in her journey as a woman engineer. We spoke about topics around diversity and inclusion and just a lovely story from Devendry. So that’s episode 24. If you haven’t to listen to that one yet, have a listen. And yeah, give us some feedback. Give divendry some feedback. I mean, it’s an incredible story around her career and how she progressed and some of the challenges that she faced. And again, just highlighting some of the important things such as diversity, inclusion, culture, and also just the stem field.

01:20

Speaker 1

We spoke about what the work, or not enough work being done around the youth and promoting some of the technology and science and mathematics obviously topics. So that was episode 24 this week, episode 25. We’re very excited to be speaking with Vanesh Maharaj, who is an excel member of Misa Africa, who’s obviously part of the african chapter of Misa International. But Vanesh is also the associate director for smart manufacturing at PwC, where Vanesh and his team assist their clients with making products quicker, cheaper, and of better quality. But Vanesh, we’re really looking forward to chatting with you today about something that I’m going to label as. I’m just going to call it the manufacturing opportunity for South Africa and for the african continent. We met Vanesh long time ago, many years ago, but just over a year ago, we asked Vanesh to help us.

02:15

Speaker 1

We had a little get together for a couple of customers and partners, and we asked Vanesh to help us with speaking topics. And he was very quick to suggest the topic of the local manufacturing opportunity. And he speaks very passionately about increasing the manufacturing output and competitiveness of Africa and South Africa. So that’s what we’re going to get into a little bit today. So, Vanesh, welcome and thank you very much for joining the podcast.

02:45

Speaker 3

Thank you, Jaco, I really appreciate the opportunity. Looking forward to it cool.

02:49

Speaker 1

So, as always, we’d like to get to know you a little bit better. And before we started recording, we spoke about, or you spoke very passionate about where your roots were and where you started, which was in the sugar industry.

03:01

Speaker 3

Yes. Had a very interesting start. We wrote my final exam during the elections in 94. So whatever else was celebrating, we are swatting. Then 95, I started in the sugar industry. Elova Sugar offered me an engineer in training program at the Pongola Sugar mall. So Pongola is 380 k’s out of Durban. So it was quite a trek from home. Yeah. And at that point I was the only indian person in the town. So it was very interesting. So that helped me made friends. So the instrument foreman, Andres Lewis, and. Yeah, he then took me to the country club and all the stuff, so we made friends there. So rugby on Saturdays, soccer on Sundays. So that’s. I fitted in the Pongola community. Yeah. Amazing.

03:52

Speaker 1

But all things that gave you a good grounding and reference and experience, that’s valuable today.

03:58

Speaker 3

Yeah, no, it’s fitting in. Accepting our diverse cultural. Understanding things from other people’s perspectives is very important because now we’re a global community. Since then, I’ve obviously interacted with people internationally, but it gave me a good foundation because coming from Durban and a close knit indian community in the area of reservoir hills where I live, you only get exposed to diversity once you go to university. And then in those four years, then you get more diversity training. And then in those days, there were days where were not really open to each other. But now, then after that, things really opened up and, yeah, it makes you a better person because I have a wider. Developed a wider perspective very quickly in those days, of course. Yeah. So then from there I progressed. I spent eleven years in lower sugar.

04:46

Speaker 3

They gave me lots of training. I finished the program in 20 months and then I became a system engineer, which I learned official dcs quite quickly. They asked me to move back to your office in Durban.

04:58

Speaker 1

And you were exposed to quite a few at that time. Really just groundbreaking technologies and diverse technologies and implementations and projects.

05:08

Speaker 3

Yeah. Well, I was completely clueless when I started, right. Because I was an electronic engineer from a university, which meant that I knew nothing about instrumentation and control. I could do anything in electronics. So this particular application I found fascinating. Yeah. And then when I went to head office, that’s when I started really doing the ground baking stuff, because then I started doing projects across Africa. Fortunately for me, in 97, Elova bought Laundro sugar in a 1.6 billion rand deal. So they bought assets all the way across southern Africa, including Mauritius and Mozambique, Swaziland, Malawi, Tanzania. So we got to do projects across Africa and we had a new DCS standardize across the system, the company. And, yeah, so I was fortunate. I was given a leading role in rolling out the first OC control system at that point in time.

06:01

Speaker 3

That is the Ompalosi sugar mole. The second instance was a Swaziland that was brand new, built a new library from scratch. Then eventually, when that phased out in 2004, we did the first Siemens pcs, seven in Zambia.

06:14

Speaker 1

Wow.

06:15

Speaker 3

And that had the Siemens guys on standby Jobo waiting for me to call him, but fortunately didn’t have to call him very often. Yeah. So it was another interesting project. But you can see IlO was investing heavily into Africa because they saw the benefits of automation in those early years.

06:32

Speaker 1

Great company. I think today they have, if I’m not mistaken, I think they have 17 sites. 17 across Africa may be wrong on that one, but, yeah, great company. And they did a lot of leading, groundbreaking work over the years. And I would imagine looking at listening to you now, probably during the time that you were there.

06:52

Speaker 3

Yeah, they had very forward thinking leadership. Our leader in our group at that time, Soviet insurete, was absolute taskmaster and we had very high standards. He standardized things across the 17 operations you speak about was not easy because everybody’s got their own minds. You got now 17 instrumentation control engineers who are trying to now coordinate, and.

07:14

Speaker 1

There’S cultural differences and companies that were previously not part of the same group.

07:20

Speaker 3

And yeah, you need a strong personality to drive that kind of thing. But Ilovo saw the benefits because when I left Ilovo and joined Cube Technologies, I saw what some of the other competitors were doing and they were nowhere near the maturity level that Ilovo had driven because of standardization. That’s why I’m quite passionate about standardization as well. Absolutely. Benefits are amazing.

07:39

Speaker 1

So from Elovo to, I was going to call it the other side of the fence.

07:44

Speaker 3

Yeah, I completed my MBA in 2006, and I hit this glass ceiling at Elovo because automation control engineers don’t get promoted beyond a certain level because they need mechanical and electrical engineers to do the heavy engineering stuff at the sugar mall. I then moved and became. I joined Cube Technologies, who was our.

08:05

Speaker 1

And you did your MBA in Natalia.

08:07

Speaker 3

University in 2002 to 2006.

08:10

Speaker 1

Amazing.

08:11

Speaker 3

Yeah, it took that long because I did read for it in the first two years, but it took me two years to write thesis because I did it on securitization. And nobody knew what securitization was at that point in time. But in 2008, everybody knew what securitization was. So I’d wait for a book to come from India. Only six, eight people in South Africa knew what it was. I could have had a very small interview set, but I liked doing cutting edge, groundbreaking stuff. I tried to push my envelope and that’s why I did it. And it helped me understand financial markets, and it keeps me in good state today in my other roles. Because finance is integral part of engineering, because of the return on investment required. Absolutely.

08:50

Speaker 1

As the business driver you often speak about, there’s always a business driver, there’s always a business reason or a business driver in terms of what we’re doing and why we’re doing it.

08:57

Speaker 3

So that’s where I joined Cube, because I really wanted to make sure I could apply my knowledge. I believe that getting trained is one thing, but if you don’t apply that knowledge, you might as well not be trained and get that knowledge. The first step is when I finished my 2004 coursework. We started a tile company, my brother in laws from scratch, called red tile in Bellito, zero base. No customers tiling for floor and wall tile. My brother in law had twelve years experience in that area. He wasn’t happy in his company. I wanted to cut my teeth in business and I couldn’t do any lobos. It’s corporate. So we started this business in March 2004, 1st month. We could not pay bills, so I took an overdraft.

09:42

Speaker 3

After putting my life savings in startup costs, we took an overdraft and I came back from one of my trips. We had to pay the bills at the end of the month. After that, from April onwards, the business survived. Yeah, no, you have to take some risks. So, yeah, then in December that year, we opened a second branch in Sanga and it took off. Yeah. Happy. Yeah. So, yeah, I was involved with that right until 2012 when I joined, sorry, 2014, until I joined Yokokawa and had to divest because of their rules.

10:11

Speaker 1

Okay.

10:11

Speaker 3

Yeah. So I did start a businesses from scratch. Took the pain and put money down. So when you put your own money down, as you well know, Jaco, I’m sure you’re shareholders. It’s a bit then applying the knowledge lets you learn serious lessons. So when I went to Cube, I knew I had to start that business also was not in the strongest position. They had a lot of potential, but it wasn’t being leveraged and yeah, so I helped grow, get Cube really well positioned. We won lots of awards. We quadrupled the turnover in the first two years because we just once again putting the right standards in place, getting people work in an organized manner. Those fundamentals are there. I always go back to basics. I don’t like doing any very fancy stuff initially until the fundamentals are in place.

10:57

Speaker 1

So in all of those roles, there would have been a thread, or there would have been a common notion of using technology to try and understand how to better improve processes and enable people.

11:11

Speaker 3

Exactly.

11:12

Speaker 1

And then that would have been common across all of those.

11:15

Speaker 3

All of those roles, yeah. So I was already involved in MIS systems at Ilovo, right? Because we had these mis.

11:21

Speaker 1

Sorry, Vanesh, we often use a lot of tlas on these definitions. So Mis is information system management.

11:30

Speaker 3

Information system. So because Ilovo had diverse assets across the african continent, we had to know what’s going on in different sugar moles. So we had reporting, so we had to integrate with other systems to bring the reporting back. The directors had a meeting every Monday morning and they didn’t know what the results of all the sugar moles were. And that’s why went to a well known historian company to help us integrate that information across different sites. But we also had local reporting on the scalar system we implemented. And so that was my first exposure. Then we had theft on the waybridges at the sugar moles, people doing all sorts of shenanigans with both cane and finished sugar. So we had to automate the sugar moles, connect up that to the ERP systems, putting in cameras, all sorts of controls.

12:13

Speaker 3

So that was my cutting my teeth in the information system and connecting the process control world with ERP systems, understanding.

12:22

Speaker 1

The value of information at that time.

12:24

Speaker 3

And camera systems, analyzing images, all those kind of things. We did a very interesting project, counting bags of sugar once again in Zambia with camera systems and different, identifying as different kind of bags. This was 2001, I recently saw, I.

12:39

Speaker 1

Can’T remember what application was, but I saw somewhere there was a company, I think it was in North America, where they actually do landfall sites. They use drones with various camera technologies to understand the density of the landfalls, to understand the capacity, and that’s actually being integrated into their scada. It’s amazing. So all of these sort of understanding what is important, what’s being tracked, what’s being reported on, what decisions are being made based on what information, using all of that knowledge, all of that process knowledge and understanding today in your role, and that’s essentially what you do within smart manufacturing, is understanding how to use and apply all of everything that’s available because there is a lot available and how to apply that and make information available, better decision making and ultimately return on money spent.

13:34

Speaker 3

So this industry 4.04 I hype now it’s not for you.

13:39

Speaker 1

And I’ve got an industry four o.

13:41

Speaker 3

Something every now and then plug and.

13:45

Speaker 1

Play, just throw them in the dvd 2.1 I think.

13:49

Speaker 3

Yeah, so it’s so sad. But you and I have been in, all of us have been industry for a long time. We know industry 4.0 started with profibus way back in the early late ninety s and we are then getting information from electrical devices and then profine. Net came out profibus for PA and we started getting all the information. So now what is this hype is stuff that we’ve been doing is this is a cloud has become a big enabler right to that. From our smart manufacturing point of view, what we’re doing now is just using the cloud to make it more accessible to our wider audience. But from automation control point of view, we’ve already always had this information.

14:30

Speaker 3

It’s just been locked up in our historians and in our scalar systems and management didn’t realize the value of converting that data into information and then giving them insights for better decision making, which is what we now do in smart manufacturing.

14:45

Speaker 1

Absolutely.

14:46

Speaker 2

And I also think a little bit in the, I want to say the olden days, but in those older technologies it was also not that accessible for those people to actually get it out.

14:56

Speaker 3

Correct.

14:56

Speaker 2

There was a little bit of proprietary protocols and you had to add some skill to.

15:00

Speaker 3

We had to use deep box to get stuff out of easy.

15:05

Speaker 2

And I think the technology is actually also catching up. It’s stuff that we’ve been doing. But the whole notion about using open standard technology to get data out of these storage is making it easier for that data to be available through the entire organization.

15:17

Speaker 3

And now the leadership appreciates this and that’s what we’re doing now in smart manufacturing is we call it connect and optimize. You connect, absolutely. You connect people to people, you connect.

15:27

Speaker 1

Systems to systems, machines, cheap networks, cheap devices. It’s more possible than ever.

15:33

Speaker 3

Like Ethernet has become pervasive even in automation, industry.

15:38

Speaker 1

Protocols and cons and the.

15:40

Speaker 3

Cloud subscription services from any you pick, whoever my Google, Microsoft, whoever, it’s now a platform as a service, software as a service, no large investments, no large deployment costs. You can purchase a quarter of a server, 20 megabytes of ram, and then scale it up overnight if you want to. It just depends on your budget, right? So that’s what we see the trend going towards. And we see that the gap is in the market in South Africa is that our maturity level in manufacturing is quite low from tooth perspectives. From a lean six sigma point of view, we haven’t got those basics down. To eliminate the waste, we did a project last year with a client. Just by applying lean principles, we increased their throughput by 22% without one cent of capex being spent.

16:30

Speaker 3

Because setup times reduce, tea breaks, lunch breaks wasted time on breakdown. Now, maintenance maturity in South Africa is another thing. It’s very immature. Some obviously pockets of excellence here and there. But from our experience and our surveys conducted, people, asset management as a holistic view has not matured. And hence analyzing assets, the criticality of the asset, how do you then maintain that asset? Depending based on its criticality and all the stuff around it? There’s a lot of work to be done and Misa will be having a webinar on that in coming months based on that asset performance management and around those topics, because we see the need to educate people around that. I’m busy with a large client in the Cape area. We have to take them through a journey and that causes breakdowns, which then increases your costs, reduces your efficiencies.

17:26

Speaker 3

And in the 22%, about 50% of that was breakdowns. So if you move from reactive maintenance to planned maintenance to condition, Moyer based maintenance, then predictive maintenance and eventually prescriptive maintenance. Yes. Now, some people don’t even know what the last two categories are.

17:46

Speaker 1

Yeah, exactly. They don’t get to that point.

17:48

Speaker 3

They’re not even aware of it. So we call it unconscious incompetence. You don’t know what you don’t know.

17:54

Speaker 1

Unconscious incompetence, 100%, I think a big thing.

17:57

Speaker 2

I think we had a webinar with Walker. Sure, don’t ask me the episode. We’ve also talked about a little bit again about OEe. If OEE is still an available metric, and listening to what Vanesh now says about you have the data, just applying principles with no capex, really expenditure, just applying the principles to tell you what is your benchmark. I think that’s a big problem. People think I’m going to go to the cloud now.

18:23

Speaker 1

Yes, it’s easy.

18:24

Speaker 2

I’m going to spin up the server, I’m going to connect it, I’m going to throw all my data to the cloud. What are you benchmarking it against? And what KPIs are you actually tracking against it? If you don’t have that in place. And again, those. And it’s very. I wouldn’t say it’s simple, but it’s simple enough KPIs that you can configure and connect six Sigma OEe. It’s not rocket science, but it’s something that you have to put in place before you move into this whole predictive and machine learning kind of concept. And I think people wants to jump the boat a bit.

18:54

Speaker 3

Yeah. The foundation has to be strong. That’s why we start our foundation element. Even though we talk smart. Smart manufacturing is not only about technology, it’s manufacturing in a smart way. Smart manufacturing talks about your entire supply chain, end to end, your supplier, your customers, customer, and how you make, orchestrate all of that in one well oiled machine. And that’s where you talk about the foundation. The foundation is weak, your building is going to crumble, and the foundation elements must be there. You must have the right processes been done as efficiently as possible with the right people doing those processes. So people process technology. That’s the fundamental equation here. Right? Of course. So once you got that platform down, then this client, Oee was not measured. In some instances, we find some clients aren’t aware of what OEe is and the components of OEE.

19:46

Speaker 3

And hence we then use technology then to give them visibility, a cloud based dashboard to calculate, show them what the OEe was. And now they could see what the problem was, availability, throughput, or quality. And then they know where to zoom in to look. Because if you’re not producing, you’re not sweating your assets in this day and age, then how do you become globally competitive?

20:03

Speaker 1

I think that’s what sweating your asset does not mean. Running it until the dusk, that’s not sweating an asset.

20:10

Speaker 3

Well, that comes back to another point. Is that also planning for redundancy? Right. Your whole asset lifecycle management. And we find some South Africa, because there has not been enough investment in the manufacturing industry in the last 20 years. And that’s why we’ve been deindustrializing, because we’ve been importing as cheap pipper to import. Some assets are reaching end of life, like our power stations. You well know. Right. But those replacements should be planned long ago, not being done now. It’s similar industry. Some clients you’re dealing with now, they got assets that are 30 years old, 33 years old. Imagine how old that technology is, how inefficient it is, and how expensive it is to maintain. It’s cheaper to replace that with newer technology, improve your efficiencies from both energy point of view and effort point of view and then kick start your plant.

20:55

Speaker 3

But clients, they haven’t got that asset lifecycle mindset yet. Because of maturity.

21:01

Speaker 1

Yeah, definitely. Well, maturity and education enablement. We find that we often speak about maturity and we speak about common knowledge and we speak about understanding. But I think very often there’s a big portion of education enablement, skills transfer, knowledge transfer that’s lacking, that we haven’t really seen in terms of people that potentially were close to the processes driving the processes involved. And a lot of those people are retiring or have retired. And very often there’s a skills transfer and knowledge transfer that hasn’t happened in those cases. In those instances.

21:41

Speaker 3

Now, you’re definitely right. And that is a key factor here, is how do we then leverage that to the benefit of the south african economy? Because wherever there’s a problem, there’s also an opportunity.

21:52

Speaker 1

Of course. Absolutely. Yeah, so you mentioned it now and I mean, we want to get into this. Obviously, you and your team, that’s where you are. You’re in the coalface. Manufacturing, mining, manufacturing, helping these companies, helping these people, being in that environment every day and understanding some of the challenges that we face. And obviously the view that you have on it is maybe a little bit wider and bigger and broader as well. You look at it from a global point of view. If we look at manufacturing as part of South Africa’s economy, I think the last statistic that I’m aware of, that I’ve seen was that it’s 12% of GDP.

22:31

Speaker 3

Correct. And dropping and dropping.

22:35

Speaker 1

Exactly.

22:35

Speaker 3

It used to be 13% a few years ago and it was 25% in 1994 and 95.

22:40

Speaker 1

Yes, exactly.

22:41

Speaker 3

Financial services have really crocketed in the last few years. Yes, but it tells you what’s happening. You can see the warehouses coming up on the side of every highway. It shows you a net import to.

22:51

Speaker 2

The airport every week.

22:54

Speaker 1

There’s almost, and I mean, there’s nothing more indicative than that. You just take a drive around the sort of East Rand, Kimpton park sort of area, you just see a vast number of.

23:06

Speaker 3

Scary part that’s all importing. And that’s where the challenge is for us. And that’s why we as PwC on this driver. And that’s why I’m glad you invited me to come here because we have to share the knowledge, educate people as where the opportunities lie, how they can leverage opportunities because they don’t know what they don’t know. We have to share how there’s all these emerging technologies, people don’t know whether it’s hype or real, what to apply first, what gives them the best return on investment. It’s such a confusing time now because you got clients one side demanding products, customized lot size of one, but they wanted the lowest cost and they wanted yesterday. Right. How do you deal with all that?

23:42

Speaker 1

So we obviously look at, when we say the manufacturing opportunity for South Africa, there’s obviously a global view as well. I think there’s an element that’s south african specific and there’s an opportunity that’s south african specific, but then there’s also a global reality and we see a lot of other countries as well where they’ve lost a lot of their manufacturing capacity and capability and output to countries like China or Brazil or various others. So there is a global view as well that we have to be realistic about. So it’s almost understanding how we can improve the south african situation and opportunity for Sadiq or southern Africa and the role that we play with our neighbors.

24:28

Speaker 1

But then there’s also another view of we probably have to be realistic about our ability as a global competitor and understanding can we be a global competitor and how we become a global competitor. And that is the challenge for all of us in South Africa, not just a couple of key individuals. There’s probably a long term view in terms of our sustainability as a country and as a nation that we have to take on that opportunity as well.

24:57

Speaker 3

Yes. So you make a very important point here because you look at mature economies, they’re all built on the back of manufacturing. Yes, because of the multiply effect of manufacturing. Right. For every job created in manufacturing, it creates four other jobs in the economy because it describes raw materials one end that goes back to farming and mining, and forwardly it goes to retailers and eventually to financial services. So manufacturing, you can look at even UK, although they’ve now matured to a tertiary services economy, they’ve built in the back of manufacturing. The US strong in manufacturing east, all manufacturing challenge. So we will not get our economy kickstarted. Manufacturing, we have to get manufacturing right now. How do you become globally competitive? Right. Unit prices? Right. We have this ambition in South Africa to do import replacement. We’ll talk about the stats later.

25:47

Speaker 3

But how do you do that? You have to have a competitive price point. Unit price must be comparative to what’s being imported for it to make economic sense. Because the current business model of your customer is based on that unit price. If they buy higher from you, they’re going to pass the cost on to their client. Is their customer going to end customer going to keep buying from them or go to another competitor? And it’s the sad thing, South Africa, is that we don’t have the local pride. Proudly. South African is a brand they’re building up. But how many of us put South Africa first? When we go to unfortunately pick on this name because of the common name. But if we go to China Mall, it’s cheap there, we buy it. It comes from China.

26:29

Speaker 3

We don’t go to the flea market where south african manufactured goods are made and they cost a bit more. But because it creates south african jobs, if you buy there. No, we go to the China more because we are worried about what’s our pocket. In fact, we don’t look at the entire ecosystem. So money goes, rather go out the country and keep you to a person, you pay maybe 10% more and keep the money in the country and help grow that person. Eventually that person’s price will come down because they get the economies of scale. So that is our fundamental challenge. Right. So in my view, what we need to do is in South Africa is you have to do two things. Bring down unit costs by improving efficiencies and you can only cut costs at a certain point.

27:09

Speaker 1

I just quickly want to pause on that unit cost. What role does the availability and cost of electricity play in that? And the availability and cost of competent labor and people play in that unit cost.

27:23

Speaker 3

Yeah, well, the electricity obviously is significant because if you talk about oee earlier availability of plant, no electricity, you probably shut your plant down. Right. But I’m hearing more and more manufacturers becoming independent. They are going off grid. One person, the guy saw my solar system, told me, you want to help the chicken processing plants. Almost off the grid. Yeah, I’m nearly off the grid. I’m busy fine tuning my system before I go off the grid.

27:52

Speaker 1

Problems of these inverters, is it, I’m.

27:55

Speaker 3

Sweating my assets, so I want my strong Roi, so I do it at home as well. So basically the idea, every hour they lose 25,000 chickens don’t get sorted. So they went full solar with backup generators, completely off grid. So that’s one solution to deal with. But if you have the real estate to do it, so mines can do it. Luckily, this 100 megawatt limit now will encourage more of those investments. But the guys now in Clempton park, in those areas, they don’t have such rooftop capacity and generators and diesel are expensive, so it will be disruptive. But then the opportunity there is become efficient. So with a client we helped last year, we showed them the initial brief was double the capacity because that was the nameplate of the plant. But then Covid hit in March, and they couldn’t sell it.

28:44

Speaker 3

So no matter how much of that product we made for them, they couldn’t sell it. So we flipped and pivoted to say, okay, how do we reduce your cost now? Because now it’s a cost focus. So we proved to them, you can make the same products in that three day window instead of five day, the same volume, two days. So you shut your plant down for two days. So if you become more efficient and you still have all these electricity disruptions, obviously it’s for certain process industries, it doesn’t work, because once you shut down a process industry, plants can take a few days to recover. But people are producing in factory automation types and producing widgets, or in this way, there’s not too much of processing. Maybe there’s a packaging plant or something, or blending or whatever. You could do it.

29:21

Speaker 3

You could do it. And that’s how you avoid the disruption. And it’s all about creating more efficiencies. Then you can have the downtime. And in the downtime, what do you do? Maintenance. Yes. And then you increase availability of plant even further, because lots of people under so much pressure, they run to failure instead of.

29:36

Speaker 1

And it’s often why there is no maintenance, because there’s no downtime. We can’t afford the downtime.

29:40

Speaker 3

Exactly.

29:40

Speaker 1

Maintenance.

29:41

Speaker 3

And that’s exactly the situation we had with our client, is that they were chasing their chickens, chasing the running around, because it was a vicious circle until we asked them to step back, look at asset tactics, look at asset physicality, then plan your maintenance around that. And then within two months, they had one whole week of shutdown to maintain the plant without disrupting manufacturing. So that’s where we have to look at the business holistically. People work in silos, and that’s why we talk about connecting is so important. Manufacturing must talk to sales and operation planning must talk to the boardroom. And everybody must work in the connected supply chain environment and synchronize everything, because everybody has impact. It’s one connected supply chain manufacturing right in the middle. It plays a pivotal role. But silo mentality does not work.

30:27

Speaker 2

And I think it’s going to become even more critical going forward. I mean, just last week in the news, it’s two plants. Now. The first plant was clover in Lufthenburg, citing bad water supply, bad infrastructure, bad electricity. They want to move that factory, they are moving astral. The astral plant down in stundaton, same story. No water, no electricity.

30:50

Speaker 3

They got a court order and doesn’t help. It’s so sad. And that’s the fundamental, is that business will go where business is made easier. Right? So this is just a microcosm of a bigger issue in South Africa, because we don’t have FDI, foreign direct investment in South Africa, because we haven’t got a business friendly environment. We talk about policy uncertainty all the time. Until those things are sorted out, we will not attract foreign investment. But the other question you asked about people, I’m actually optimistic about people and skills in Africa, because you talk about the digital dividend. In Africa, we’ve got the youngest growing population. All of them are digital natives or majority of the younger people. So then they will adopt these new technologies, much easier.

31:38

Speaker 1

Easier, correct.

31:38

Speaker 3

Than the older people. Look at these kids who don’t know how to drive an iPad or reading a manual, right?

31:45

Speaker 1

Twelve years old.

31:46

Speaker 3

And so we understand there’s some shortcomings in our education system. It’ll take a while to fix that. Or within the SIMC, we’re looking at alternative education systems like the european model you study for in Europe. Study for six months, you work for six months, and then that’s how you get your degree, right? And the benefit is twofold. First, you get practical experience, but when you work, you get paid. So it takes the financial pressure off. You know, the majority of people in traffic can’t afford school, university fees and things like that. They come from very poor background. So you create this ecosystem where people commit to hire those people for the six months to do some practical work, and then they go back again and then still have the job and come back.

32:26

Speaker 3

But it requires all of us to work in a cooperative manner and not be selfish, and that’s what’s holding us back. In South Africa, my view, we all think about ourselves only we don’t think about the community. If you look at the eastern cultures, Japan, Korea, why are they flying? Community driven. They look at the bigger picture. What is the great, good Nordics we.

32:47

Speaker 2

Talked about the other day where it feels that there’s so big community in other parts of the world where people will share knowledge, they will share findings, they will share. How do I actually solve this problem? They will share it openly. In South Africa, it’s still a little bit of. It’s my job security. That’s what I did. It’s the eye, right? The eye factor. The eye specialist, like you always called it, but that’s the truth.

33:13

Speaker 3

But come back not to be probably south african. If it’s a south african thing, we think import is better. We don’t really give ourselves a credit. Look at the Americans. There’s an american flag outside every house. How many of us got flags outside our house? We are a diverse society. We haven’t properly integrated yet because of all the challenges. And some political parties don’t really help us do that. They keep creating more divisions. But then we have to get past that and become proudly south african, put our money where our mouth is and help kickstart our economy together. And putting money where your mouth is starts with the government as well. Right. Because the other point of improving localization is that you either do import replacement or you do export growth. Right? Yeah.

33:59

Speaker 3

So in order to do that, it comes back to the same unit cost. If you want to export, you’ll be globally competitive. So how do we get this right? Initially we don’t have the scale. Look at our global competitors. Look at machines. We did some work in the steel industry. They have got no chance against the eastern competitors because of volume, sheer volume and logistics. The networks are so well organized. We’ve got congestion at urban harbor. So all that time and cost delays costs money. Right. So we first have to make sure. How do you get unit costs down? Get some government support initially. Give each industry a certain period of time to ramp up their production, get the unit costs down, then give them a period to stabilize. And using bilateral agreements, export treaties and things like that, start exporting to Africa.

34:52

Speaker 3

Currently, if you look at the stats from businesses in Africa’s work we did last year, Africa, we produce about 2% of what Africa imports. Yes, 2%.

35:03

Speaker 1

2%, yeah.

35:05

Speaker 3

So we can easily triple our capacity. And we’d be fantastic. This on import replacement. If we replace two and a half percent of our import, it’ll be about another 30 billion rand, 8000 jobs that we can create just by replacing two and a half percent of our imports.

35:23

Speaker 2

But you make it sound so easy.

35:24

Speaker 3

And a lot of it, and that’s the question, is not easy.

35:27

Speaker 1

Policy is a big driver. Is a big driver.

35:30

Speaker 3

Yeah. And the policy uncertainty. We keep flipping and flopping. At least now with energy thing, we got some uncertainty.

35:35

Speaker 1

Exactly. That was a big positive.

35:37

Speaker 3

Yeah. It’ll never take off unless you have some sort of governance supposition. The reason why our automotive sector is a perennial survivor, even in the last year’s recession, they were still 2% up, was because they get government incentives. That automotive development program is a long standing program that’s produced lots of good results. Right? So why can’t we have that in other parts of the economy? Because all those cars, most of them exported auto, right. And drive countries, they generate forex for us. It helps to balance our trade, strengthens the rand, you name it, right? All these benefits happen. So if we’re going to get manufacturing competitive, government has to come to the Party, provide some subsidy for a certain period of time, get the unit costs down. Those will then help open up more markets for us. Africa is waiting there.

36:24

Speaker 3

They want to do business with us. The Africa Free trade agreement is in place. And from the before SA work as well. It shows we can get stuff to our african neighbors in ten days versus 45 days from the east or the west, logistically. So we can get it to them in one third at a time. But our price is wrong.

36:44

Speaker 1

Price is wrong, yeah, that’s why it’s.

36:46

Speaker 3

Not.

36:48

Speaker 2

Even with that time delay and distance from a logistic perspective, we’re still not at the right price point.

36:53

Speaker 3

No, that’s why they import. And secondly, this whole Covid thing, right? Localization has become a big thing.

37:01

Speaker 1

Yeah, I wanted to chat about the effect of COVID because that’s 100% localization.

37:06

Speaker 3

And when Derek Hanukkah was still DtI minister, we had some conversations with him. Part of, I think it was. Yeah. Then he said our neighbors also have the same localization drive, right? So they won’t destroy us holistically importing into exporting to their countries, because they also need to create jobs. And the same multiply effect applies to their economy. So then create local manufacturing capacity. We know, like some companies went in the four ways in Africa and it was a disaster. Right. But then, now with the free trade agreement, let’s create enabling environments. Why don’t build a factory that does assembly in that country that you produce the products here? Like how we assemble cars here, we produce it. It’s a win. Then the finished product is still produced there, but we also get some benefits of creating the components.

37:54

Speaker 3

So there’s lots of creative ways of trying to resolve this. But we need support of government to help us get the unit price down.

38:02

Speaker 1

So policy, fiscal policy is going to change.

38:05

Speaker 3

And incentives, there’s more incentives.

38:08

Speaker 1

Yeah, absolutely. It feels like a couple of incentives that we’ve seen over the past years. Some of them work very well and some of them never have really launched or got off the ground. But I think the incentives, important parts. We spoke about the multiplier effect. We spoke about just a percentage of GDP, obviously hand in hand with all of that thing is obviously job creation and unemployment rates. We spoke about the export market, strategic industries. What are some of the sort of strategic industries that’s been identified as high impact for South Africa? So I’m obviously thinking minerals, mining, manufacturing, what are some of those industries that.

38:49

Speaker 3

Yeah, so metals is a huge one, right? We’ve got large iron ore deposits and things like that. So metal processing. Well, even all your PGM groups, right, as well, just the precious metals and the platinum group metals, we can see the new potential battery technologies and come up with that. We know with catalytic converters now becoming less popular, that market eventually will die for platinum. But you have to find alternative uses for it. But this is steel. You can hear all the ruckuses and engineering news. There’s wars going on about steel and steel pricing in Africa and the shortage supply and the tariffs are protecting us, protecting certain plays in the market. And constraining is. But that’s another huge opportunity for us, right? Because if we can get the efficiencies right in the entire supply chain, then we can alleviate that.

39:34

Speaker 3

We help both the producer of the steel and in the downstream value adding organizations so that they get the best input prices and they can pass it on to their clients, because now they feel it’s cheaper to import the raw materials and then do further processing if they can get access to it. So there’s constrained supply as well as a high price, which shows you volume and price are correlated.

39:55

Speaker 1

Yeah, for sure.

39:59

Speaker 3

We spoke about even tetrochemicals, right? So he mentioned that one, tetrochemicals, we’ve got large companies, I don’t mention names, but we’re very advanced in that area. We’ve got groundbreaking technologies and we’ve got multinationals.

40:11

Speaker 1

We have refining capacity.

40:12

Speaker 3

Yeah. And we’ve got large multinationals. Right? And our refineries, okay, they’re all assets, right? And now all environmental legislation is going to come about. There’ll be lots of billions of rams spent to control emissions and things like that. So then how viable are those businesses? But the defined chemicals, all the other chemicals can still be produced. What about now, the whole hydrogen economy, that’s going to come out of. So there’s a whole lot of potential. So every cloud’s got the silver lining, right, as they say.

40:38

Speaker 2

And I think that’s one of the examples where policy actually was a good policy, especially in the petrochemical. If you wanted to sell petrol in South Africa, you had to have a refinery in South Africa. That’s where the consortium was done for the refinery in Durban. All the players. But again, that shows you how policy can create a very good situation where, hey, now we’ve got three or four refineries in the country. Obviously we don’t have our own oil. But just on that basis, that policy actually driven to have those refineries.

41:10

Speaker 3

But the scary part is it’s cheaper to import the fuel and refineries in South Africa. That’s why you’re just. Two large refineries are currently shut down. Didn’t impact our fuel because it’s cheaper to import fuel. So we don’t want those to be converted into large tank farms. Right. We rather.

41:28

Speaker 2

Well, it’s already happening at Sultana.

41:31

Speaker 3

Yeah, Sultana is a gas import project is happening there. But we should rather get our refineries to become more efficient and then continue refining. Because there’s thousands of jobs in the refineries. It’s a highly technical, dangerous space to be in. But we should remember what each one of those people probably support. A household of four. So if those people, thousands lose their jobs, maybe four times that thousand is going to be going hungry.

41:56

Speaker 1

And not just the households, but actually the towns built around those businesses and those companies as well. Communities.

42:03

Speaker 3

Yeah. If you take like Nachov, that’s a huge.

42:09

Speaker 1

Mean. Just a quick Recap. The top export markets or partners for South Africa. So we’re talking about Germany, USA, UK, Japan, China. Those are some of the good examples of where we’re exporting to.

42:20

Speaker 3

And the interesting thing about that is those are advanced economies, right? What did they export from us? Highly technical stuff, like aeronautical parts, automotive parts. These are not simple things to make. So why do we keep selling ourselves shorter? South Africans, we can be there up with the best, but we’ve got the price right for a highly technical item. So why can’t we do with the rest?

42:43

Speaker 1

With the more volume based.

42:45

Speaker 3

Exactly. And I talk about pockets of excellence, right? There’s an example of a company in the Eastern Cape. And we know all the challenges in the Eastern Cape, right? Yeah. These guys almost went out of business in 2008. They took their last 3 million rand. They backed themselves, they built a highly technical piece of kit. They put the four IR technologies around it. And today, South Africa is only 5% of their business. Everything is export driven. They commission using augmented reality, they design using digital tools. And they sell supply all over the world. They’re fully four IR industry 4.0. And that’s given a competitive edge. So why can’t we repeat that kind of thing with other industries. Is there inertia, government legislation, but the people part as solutions there as well. Right. The connected worker technology we can talk about a little bit later.

43:38

Speaker 1

I want to chat about the connected workers I almost want to look at. Okay, so we spoke about policy and government, fiscal policy and all of these sort of drivers that we potentially, as small pockets and groups of people, don’t have a lot of control over in terms of sort of setting the agenda for some of that policy. But if we talk about some of the things compared to other parts and other countries, we spoke a little bit about technology and innovation. We spoke about the institutional framework. That’s where the government piece and role comes to play.

44:11

Speaker 1

I definitely want to spend a little bit of time talking about the human capital because the human capital, that is not only the availability of a skilled workforce, but that is also a very key important element in terms of how the technology and the innovation you spoke about is being deployed within these manufacturing companies. It’s about the people. It’s about the people that deploy that technology and how they use it and how they interact with the technology to improve the processes. So when you’re talking about the connected workforce, what is your definition and what is your description of the connected workforce?

44:51

Speaker 3

Okay, so before we go there, right, let’s talk about the people side of things in a manufacturing environment. So despite common myths, industry 4.0 does not cost jobs on a net basis.

45:08

Speaker 1

It’s going to take the jobs, the.

45:10

Speaker 3

Machines take the job, take my job. Exactly. But from a net point of view, and we understand what happened in large local multimedia companies and in the banking industry. People lost their jobs because automation. But if you do something that’s repetitive, where you don’t really apply your mind, a machine will do that. But we are, human beings should not be designed to do manual labor, repetitive tasks, because we also get bored. Right? So it’s not mentally stimulating. So that’s what four IR does. It helps create more meaningful work where you require to apply your acumen and your creativity. That’s the most important thing. And that’s come back to your point. People interact with the technology and all the projects.

45:51

Speaker 3

In my automation career I’ve done from Tanzania all the way to South Africa, is you give the people a tool and they’ll tell you how they can use a tool in a different application to improve the way they do their job. Because we are too far removed. The person who does the job knows the job best. You give them the right tools, they’ll leverage those tools for even better output outcomes. So people are critical to the fourth industrial revolution, contrary to the popular belief, our research in the 2018 global study we did, the digital champions, the highest level maturity. They want to hire 30% more people in the US. You spoke about all the stuff before we joined this call, but they have lights out factories there, right? Robots doing everything.

46:31

Speaker 3

But they hired more people because they require the data to be processed, analyzed. So you need more people involved in the data science side of things, but net increase in jobs, but you need those more skilled jobs.

46:42

Speaker 1

Yes, correct.

46:43

Speaker 3

So that’s why we drive skills, and that’s why we’re driving the thing of the future of work. And in PwC, we’ve got some tools that we use to say, if you’re going to start this digital transformation journey, these are the current jobs you have today, which jobs will become redundant and which new jobs will be created. And then you start today with upskilling, reskilling, cross skilling, those people whose jobs are in jeopardy, so then they can take on the new jobs that are created so they don’t lose people in the system.

47:11

Speaker 1

And I mean, there are industries, there are definitely industries where there is a risk, a very high risk to, I think, of sort of in the mining space, for example, and the optimization and the robotic mining processes. There’s definitely a threat. But to your point earlier, we’ve got to start looking. We should have started looking at that already to understand, all right, the redeployment of those people and their abilities to be creative, to be contributors and decision makers. The skills required to do that is something that we should be considering or have considered a while ago already, to not get to the scenario where any of that potential innovation and opportunity is being stopped because of the risk of those people losing their jobs and communities going hungry.

48:03

Speaker 1

And all of these things need to follow that sort of view and progression to eventually, when we get to that point, that those people are able to be easily integrated into roles and positions where they do add incredible value. And none of that progress is then being stopped because of the potential risk to job losses.

48:24

Speaker 3

So it’s undeniable, right? In South Africa, because of our history, there’s structural unemployment. That’s why we’ve had jobless growth since like, 1994. Right? The problem is, once again, it’s policy correction. Why must everybody come to the cities to find jobs, right? Certain mine workers above a certain age category will not fit into the information age. We have to be realistic about that, right? They’re probably hardly literate, but we still have an agricultural sector that’s falling behind. Why not upskill those people? It’s also out in a rural area where the mines are and move them to the agricultural sector, get our whole land reform thing sorted out, get us back to being a large exporter of agricultural goods, and those people can easily move there.

49:13

Speaker 1

The agri industry, interesting enough, is one of the industries where we’ve seen really good growth, positive numbers, at least over the last.

49:20

Speaker 3

Mining, agriculture, and government were the last in. According to PwC’s latest economic report, mining, agriculture, and government growth had growth. Manufacturing did not have growth. But look at food and Bev. It’s one of the most robust. It’s 24% of South Africa’s manufacturing capacity.

49:34

Speaker 1

Very resilient industry for obvious reason, right? Absolutely.

49:38

Speaker 3

And I had a culture that has to be with a client last week talking about their digital journey. They very advanced. I was so proud to hear. To hear what they were doing. They’re exporting actively into Africa. They created a hub here in Gauteng to export into Africa, and they are now targeting the China market. They understand the one point, how many billion people in China they’re going to export there because they got the efficiencies right, they got the logistics right. So it does exist. We can do all those kind of things.

50:05

Speaker 1

So what is that magic recipe? Or what is the magic wand? Let’s call it a recipe. So we spoke about the efficiencies, spoke about the unit cost. Well, that’s a result of the efficiencies, I think. There’s a unit cost, the understanding of the logistics. What does that recipe look like in your mind? That magic recipe.

50:28

Speaker 3

Okay, so the magic recipe here is a complete working ecosystem, right? So every part complements the other part. So for manufacturing to become globally competitive in South Africa, each manufacturer must take it upon themselves to first apply all the lean principles to get the foundational principles sorted out. Then they have to apply, which is applicable for IR technologies, to give them the next leg up, because that’s given the next competitive advantage, because the comparators from the east used to have the low cost labor advantage, but even those guys are now making people redundant because technology is making them even more competitive. Now, imagine what happens to us with our strong labor unions in South Africa if we don’t get this right.

51:14

Speaker 2

But I just want to. It’s very important that you said apply the four IR technologies that’s going to fit your situation.

51:22

Speaker 1

Absolutely.

51:23

Speaker 2

I think we see it so many times.

51:25

Speaker 1

We joke about it doesn’t have to be a rip and replace.

51:29

Speaker 2

And we see it so many times about, okay, I want this. Why do you want it? Why, Mr. Digital officer, do you need machine learning? What are you going to do with it?

51:38

Speaker 3

Exactly.

51:38

Speaker 2

And I think that’s very important point. Sorry.

51:41

Speaker 3

That’s exactly why everything must be business case driven. And nowadays everything, the return investment must be two years or less because there’s a capital shortage, because our current circumstance, right, we’re in a recession. Before we got into Covid, this went even further backwards. So that’s how we look at it, in that we have to analyze the client’s fundamental baseline, your Azz situation and what is your to be, and work out a journey there that makes business sense. So in PwC research, there’s five reasons why smart manufacturing projects fail. Lack of leadership, management change their mind. They’re not committed to the process.

52:17

Speaker 1

Bigger picture.

52:18

Speaker 3

Yeah. People work in silos, so they don’t integrate and connect with each other. People do little pet projects like you’re talking about. I want to do machine learning just for the sake of it. But they don’t think about what the business value of it is in the working in silos.

52:31

Speaker 1

Sorry, in the working in silos. It’s not necessarily it’s nobody’s fault. It’s just because there’s working in silos, there isn’t an understanding of what I’m doing right now impacts the next person or how I’m being impacted by the previous part of the process because of these silos of information.

52:49

Speaker 3

Well, it’s all silos operation as well, because you have conflicting KPIs. We’ve seen certain instances where one department’s KPI, and this is in the steel manufacturer, by chance, is completely contradictory to the other part of the business. And it should be an integrated operation. So we have looked at. That’s why I’m saying everything must be looked at as an ecosystem that supports each other. It must be synergistic. And if it’s not synergistic, that’s why we have these inefficiencies. One part of the business is told to push as much as possible to the other part, which has got constraints on the other end. And overall, the whole business suffers because their KPI and their bonuses are based on the volume they produce, not what the whole business looks like. And we see this in more and more companies. So the other reason why.

53:30

Speaker 3

The fourth reason is people do these little projects, but they don’t think about scalability. So I do it in my little plant. And when I try to scale it, the whole thing breaks. And then you reinvest and inside again from scratch with a new what is, what’s more scalable. So these are the common reasons why these products failed. And so it must be business case driven, like you say, yml we use that and that’s why the CFO will listen to us, because we show him the ROI. So you’ll get your money back in x point of time. The client we did the transformation with just by unlocking the inventory that overproduced because of this disconnect within manufacturing, sales and operation planning, it paid for the entire fee, so it doesn’t have to cost you money.

54:17

Speaker 3

It can be a zero sum game, but you have to be smart about it. And as you said earlier, before we started this call, people must take a step back and look at the bigger picture and take a breath and not just dive in. And so the value formula is this step by step, look at your processes, look at where the value lies, where are my bottlenecks? Then I can then take it through to eventually realizing the business value. But it’s a very logical process, seemingly.

54:46

Speaker 1

Very logical and very straightforward.

54:48

Speaker 3

But the problem is people are so time constrained today, they haven’t got time to get up and look at what the bigger picture is and where the opportunities lie.

55:00

Speaker 1

Well, the reality is it’s like running 100 meters. You’re doing the 100 meters race, you’re sprinting and you’re going for first spot. And then halfway through the race you realize you’re wearing the wrong shoes. You’ve got your boots on, you can’t stop to change your shoes and put on your running shoes. So you just carry on running with your boots and you just caught in that cycle. You just caught in that cycle.

55:20

Speaker 3

Yes. And I went through this when I joined Cube. The reason I managed Cube is not because I’m the smartest person around, is because I looked around and said, this company is in famine or in feast. Like all project companies, somebody needs to be looking ahead and creating the pipeline of business. Not that I finished one project and I’m looking for the next project. So I took a step away from the engineering side of things. I delegated that to the engineers, and then I looked at the business development and looked at the horizon and started creating that pipeline to make the business sustainable. Then you create also slas to create sustainable income to help you with your fixed costs on a monthly basis. And that’s how you become.

55:59

Speaker 3

But the leadership, they were engineers looking down, logging into program but not looking at the next thing. So this is what we need in South Africa, guys, leadership is take a step back. But I had a conversation with a client yesterday. We are too busy to even help figure out how to solve this problem. We don’t have enough bodies. People are off for Covid this and that. So if you haven’t got time to solve the problem today, it’ll still be there tomorrow in a year’s time. So you have to consciously make time for this. And unfortunately it requires investment in a person who has that vision. And now they create this whole digital officer or industry 4.0 officer or whatever. It doesn’t have to have that fancy native, but it’s take one person, even the CIO can do it.

56:41

Speaker 3

Historically CIO has been more on the financial side of things than managing. But now they should be looking at strategically how to uplift the business, make the business more competitive. So we are more tactical in South Africa even at some executive levels than strategic. And we understand things are changing so fast. Strategy is no longer five years normally nowadays maybe every three years you need to revise the strategy but at least have a three year view. Not, I mean survival for today and today only. Like they maintain the example I gave you run to failure because there’s no time to maintain the plant. But then that catches you out every single time. Take a step back.

57:16

Speaker 2

There’s a good story in history around that one. So Henry Ford did not pay his maintenance people the amount of time they’re actually on the plant floor. They paid him the amount of time they actually sit in the break room. And that’s a classic example.

57:32

Speaker 1

It’s actually quite reliability.

57:36

Speaker 2

That’s such a simple thing. The more time you actually reliably fix my plant and spend in the break room. Wait, then the more you.

57:42

Speaker 3

And that was the early thirty s. Yeah. So our mindsets haven’t evolved. So we have to go through this process, look at our tools, look at our solutions. Whether it’s digital or not digital. Everything doesn’t have to be digital.

57:53

Speaker 2

That’s also exactly. It doesn’t have to be something you.

57:56

Speaker 1

Install or capital invest or a new license or a new dvd or a.

58:01

Speaker 3

New software pc and even that the tools you guys sell, right. Those tools are enablers because visibility is lacking. And the power of your tool, it’s cloud based, it connects to everything. So that’s what you need, visibility. And that’s maybe you can classify as a digital tool. But what is it enabling nondigital solution because you can now make information timelessly and the correct decisions make decisions because the information is available at the leadership level. So then once you move that, then you can reduce all your losses. You can then have a greater business impact, which is improve your quality, your machine performance, or even nowadays, energy and environment are becoming very hot topics, right? Because of the whole ESG scorecard, environmental sustainability, social and governance ESG scorecard. A lot of financiers are saying we don’t follow either ESG scorecard, right?

58:54

Speaker 3

We’re not going to give you capital anymore at a good rate. We’re going to start penalizing you on interest rates and things.

58:58

Speaker 1

And rightly so. I think the sustainability has been recognized as probably the most important is the sustainability, everything else to be very philosophical about it. Just as responsible human beings of citizens of earth, that sustainability, environmental and sustainability view is ultimately the most important.

59:20

Speaker 3

Yeah, but sustainability goes beyond environmental, right? Because we don’t treat our people right. They’re not going to stay with us. We don’t give them a proper health and safety environment. If we don’t have a social license to operate in mining situations, then people, they’ve got nothing to lose when that mine shuts down because they’re not getting any benefit anyway, right? So we have a look at sustainability and that’s why now we’re going to come up with some. And PwC has released a new strategy. So we sustainable smart manufacturing, because we have to look at it once again, ecosystem view. Because if you just manufacture. Let me finish the other part. But once you achieve the business impact and you achieve your business goals, which is increasing your output, reducing your manufacturing cost, once again, unit cost manufacturing.

01:00:03

Speaker 3

So that’s like the journey you go through. Start at fundamentals, look at your baseline, look at lean principles, and then go digital later. But getting back to this point about sustainability, if you manufacture in a smart way, you reduce your environmental impact because there’s less rework, less emissions, less energy consumed. So this whole net zero commitment people are making for 2050, you can start achieving that. But then in following the smart manufacturing journey as well, you upskill and empower your people so your people get more rewarding work. The loyalty then creates, you also create a pool of more skilled people, right? So that’s how all this starts interlinking. Because then the financiers see the benefit. And there’s research done, I think, Blackrock, that the companies that have got a high ESG scorecard have the highest availability, the highest throughput, the highest profitability.

01:00:59

Speaker 3

But those guys took the step back. And then let’s go back to the people that didn’t answer the question, but the connected worker, right? So the connected worker is, I think, fundamental for South Africa, in my view. In South Africa, there’s a couple of three things, Robin, eh? The visibility across from the factory floor to the top floor, shop floor top floor, right? Because the leadership, the CEO, needs to know what’s happening.

01:01:24

Speaker 1

Somebody who’s doing that very well is Abmdev. If you look at the entire drive that they have around the brewery of the future. Sorry, just the whole way that they’ve designed the operations and their day to day plant floor, if you want to call it that, is where actually the operator is now. The center of that entire operation. The person with the most knowledge and the biggest opportunity to make the biggest difference. And they’ve built the entire brewery of the future around that notion, that principle of enabling those people and getting a better view of what those people are.

01:01:56

Speaker 3

Doing and helping them.

01:01:57

Speaker 2

And when we say building, we mean physically building.

01:01:59

Speaker 1

Physically building.

01:01:59

Speaker 2

So they whack, actual control, whack down every office that there is. There’s no more. The plant manager here, he’s sitting in his office, door is closed. Probably can’t go and talk to him now.

01:02:09

Speaker 3

So literally, open plan.

01:02:11

Speaker 2

One massive open plan operator sits right in the center.

01:02:14

Speaker 1

In the center.

01:02:15

Speaker 2

Next to him is obviously support staff. So technicians, engineers. Outside that ring is all the production people. So production managers, et cetera. Outside that is then the more higher leadership.

01:02:28

Speaker 3

Leadership, whatever is accessible.

01:02:29

Speaker 2

But everybody is accessible. And everybody sees the same screen, that.

01:02:32

Speaker 1

Same screen, the same view, same KPIs.

01:02:34

Speaker 3

Exactly. Speed of decision making, access to information. KPIs, yeah. And then that’s where the connected worker comes into play, is that a connected worker has got multiple benefits. Okay, so what’s a connected worker? This person is supported by technology. Either you can use augmented reality via smart glasses, tablet or a phone, or even smart clothing, like intelligent bracelet. Okay, so what does this give you? It gives a person access to information. It helps them connect to processes. It also then helps us track what they are busy doing. Most people are not comfortable with that. But for accountability, you need to track people. Okay, so the question is, so how do you do it? By using smart glasses, you can provide remote support.

01:03:19

Speaker 3

So in South Africa, we know we’ve got lots of machines we import from overseas with COVID People can’t travel here, support it. So what? Smack on the smart glasses. Connect to the guy in the other end, the OEM, he can see exactly what you’re doing. Help you optimize your plant, or the guys with experience, kilometers away, thousands. And you’re saving the travel costs, the hotel costs, all those kind of things. So it pays for itself in virtually the first trip you ever have an issue with, then the aging workforce. The old guys are retiring. Give them a role where they can sit in one comfortable environment, like your office here, but have a big screen like you have in your offices, and they can support multiple young people, even though they don’t have necessary education and skills yet.

01:04:05

Speaker 3

My definition of skills is education plus experience makes you skilled. People. Talk about, there’s enough educated people out here, but that doesn’t mean you got a skilled workforce, but you can’t get a job. Now you have to have a job to get experience, right? So now, with all these digital natures coming in, equip them with smart glasses or tablets, smartphones, they’re all used to this stuff, and then they go and have a chance of solving the problem. When they get stuck, they dial up the guy who’s got the years of experience. He helps them solve that problem. They’ve now learned a new skill. They’ve learned something, how to fix it. And slowly, by slowly, you’ll build it. We can’t do this thing overnight. We have to take a long term view and invest in this kind of stuff.

01:04:44

Speaker 3

And that’s the only way we’ll get it right. And then either use a tablet album, remotely, support, or the glasses or whatever. And that’s one possible solution. So we upskill people or provide remote support. To me, that’s fundamental. The third thing is Iot. It’s like everybody’s talking about it. But IIot is also important, because if you look at predictive maintenance, once again, reliability of plant. Buy cheap sensors, stick them on your machine, don’t worry, you have to wire them up. Your PLC, don’t take your spare I O cards available, enough memory in the PLC, just stick it in, connect to the cloud, bring it back in your system, and then you can see what’s going on to access that data immediately. And it’s not for tripping, interlocking. Obviously, you still follow the traditional way, but this is for maintenance purposes.

01:05:31

Speaker 3

See, the vibration is going high, the temperature is going high. Then you can start planning ahead. And then once you’ve got the data and you’re accumulating for years, you can start looking at predictive stuff, because you can see this combination of events led to that failure in three weeks time. So when I see this again, I warn you, in three weeks Sam, you need to do this maintenance. It’s very logical. But we don’t take a step back to figure out and we don’t take the time to first start gathering this information. But by the way, most of it’s locked up already in our scalars and our historians. Right. We just haven’t accessed it. Exactly. Yeah.

01:06:02

Speaker 1

Just got to be able to access.

01:06:03

Speaker 3

Yeah. Lots of companies got long term archiving. I put that in early 2000s in other countries. So we have to really go back to basics. That’s my message. There’s nothing much more we can do, but we need the government support. That’s the summary.

01:06:17

Speaker 1

Yeah, I like a couple of things that you said that I really like. I like the bit that you spoke about. Yeah, we’ve got to wrap it up. We can probably speak for another couple of hours. The first thing that you said was being selfless. Stop being selfish and being selfless. And I think in many ways you can only be something to somebody else if you’re something to yourself first.

01:06:42

Speaker 3

Right.

01:06:42

Speaker 1

So I think a lot of people, I’m hoping that a lot of people work off their premise and that’s where they start.

01:06:47

Speaker 3

You can’t give what you don’t have.

01:06:50

Speaker 1

But a very important point that you made about us being more proudly south african and being less selfish, and I think there’s got to be a realization of that and there’s probably a couple of reasons for that thinking or that behavior, but absolutely I agree with you. The second thing that you mentioned as Dee is almost to take a stoic view on this thing and worrying only about the stuff that we can control. I think the government policy drive benefit all of those things are very important. And to a large extent we can control it and to a large extent we can’t control that. And then the third one, which is something that we feel quite passionate about, that with our very small community that we have in trying to understand what we can control is exactly that.

01:07:34

Speaker 1

The community and the involvement of community and the realization we have really clever system integrators and partners, amazing customers. It seems like there’s a general understanding of wanting to do that, but not necessarily knowing how to start and where to start exactly to do that.

01:07:53

Speaker 3

And that is a kind of stumbling block. Yeah.

01:07:55

Speaker 1

And that’s the bit that we seeing in terms of, all right, we’re on board, but how do we, where do we, and who do we start with? And I think that’s why we have organizations like Misa organizations or a very important part of those organizations is also to help identify where to start doing those things.

01:08:14

Speaker 3

And that’s why we are running this Misa webinar series every month to make sure we educate people. Because manufacturing execution systems are critical to the 40 industrial revolution. It helps to connect your ERP to your control systems and get that into PQIM, production, quality, inventory and maintenance. Those are critical to connect, to have one source of the truth, dual weight excel spreadsheets, using an MES to connect everything. But if you’re not ready for an MES, because that’s quite a large investment, just connect with a cloud based dashboarding and connecting the databases until you get the maturity level where you can and the tools you provide can help. There’s other cloud based tools that you can have that can do that as well, but the tools are available. You don’t need a huge transformation. Start step by step. But do the business case.

01:08:58

Speaker 1

Yeah, absolutely. Do the business case and see where you can get these small victories by.

01:09:03

Speaker 2

And there’s a lot of loan and.

01:09:05

Speaker 3

That’S exactly why it’s very important. When you get the small victories, you get the confidence of the financial players. The CFO says, I’m not throwing money down a black hole because I gave you x million for that skater, but what’s the return investment on that if.

01:09:17

Speaker 1

You are paying million for a Scada, by the way?

01:09:21

Speaker 3