SPEAKERS:

Transcript

00:06

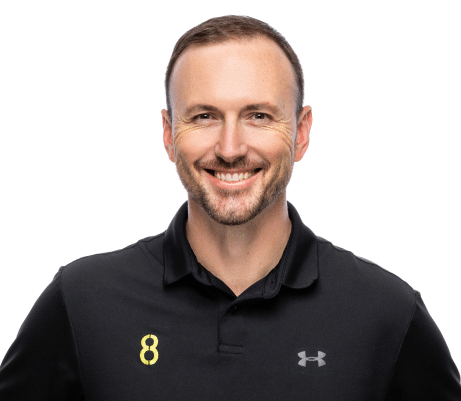

Speaker 1

Good morning and welcome to the quarterly Data Liberation Front update. Welcome to everybody here with the introductions in a moment. Thank you for joining us. If you’re online. Thank you very much. We’re looking forward to an interactive session. We’ve got a couple of polls, but nice to spend time with you this morning. So by introduction, my name is Jaco. I look after the team at element eight. If you’re not familiar, if it’s the first time you’re joining us is the distributor for ignition SCADA IoT, Universal industrial application platform, Canary, high performance time series database, CSO soft purpose built MAS recognition and of course, flow analytics hub. That’s what we represent. I look after the team I have with me this morning in person, the evergreen Clarisse.

00:55

Speaker 2

Yeah, I’m Clarice and I look after our channel community in South Africa. So if you have any questions after the session, partner like, please let me know.

01:06

Speaker 1

Cool, thanks. Larisse and Teri, hello.

01:09

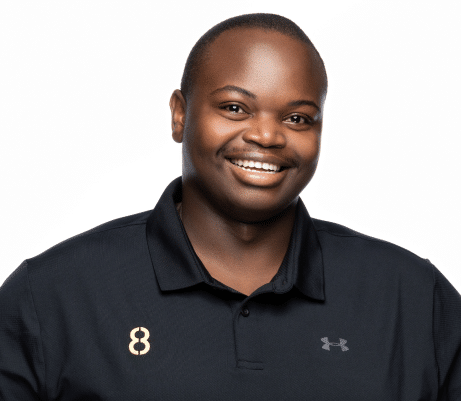

Speaker 3

I am Tiralo. Like we mentioned, I am in the customer success team and I am responsible for making sure hotness and end users.

01:17

Speaker 1

Are happy with our spot. Fantastic self proclaimed night l and consistent winner of the friendliest colleague to work with.

01:28

Speaker 4

Thanks.

01:28

Speaker 1

The rest of the team couldn’t be here this morning. We’re all doing different things. Laura Stratum was presenting ignition training in Cape Town. Gary Lowenstein is playing with our new voice from Stratus. But that’s our team with you this morning. Then across from me, dare I say the evergreen. Maybe not. Yeah, you like a fine rewind.

01:50

Speaker 5

That’s fine.

01:51

Speaker 1

Looks like the UFO.

01:54

Speaker 4

Morning, everyone.

01:55

Speaker 1

Welcome, Lenny.

01:55

Speaker 6

Thanks.

01:56

Speaker 5

I think most of the guys who know me, Lenny Smith, part of the flow team, looking after the customer success side there.

02:04

Speaker 4

Engage quite a lot of time with.

02:06

Speaker 5

Element data, our partner in the sub saharan african continent. So got some geeky stuff I’m going.

02:12

Speaker 7

To show you guys today.

02:13

Speaker 5

So hope it is valuable and informative.

02:17

Speaker 1

Looking forward. I know there’s some exciting things happening in the flow world development. So, yeah, we’re looking forward. Thanks, Lenny. And they’re very excited. Always the heroes in our community, our system integrator partners we have this morning. We’re very blessed to have Kundra and Rudy from Dana Engineering with us.

02:35

Speaker 5

Good morning, guys.

02:36

Speaker 4

Thanks for having us.

02:37

Speaker 1

We’re looking forward to seeing what you’ve done to help TCM be more efficient and resilient. Looking forward to that presentation.

02:44

Speaker 6

Thanks. Yeah.

02:45

Speaker 1

Kunrat is a self proclaimed Lego and Star wars addict, keen aviator.

02:53

Speaker 7

A big one.

02:56

Speaker 1

When you ask somebody for a photo to use for their profile, and you get photos with Star wars scenes and then, you know. Thanks for joining us. If you’re not familiar with element eight or the DLF, maybe just a quick intro. The DLF is not a political party comrade. It is rather the coming together of like minded men and women with a common purpose and a passion for our industry and for growth. What is that common purpose? It is to humbly serve our community and the industry. Probably the most important thing each one of us can do in 2023 is to learn from others and share what we’ve learned, provide intuitive solutions that scale, and to help ensure data driven and flourishing future for all. That’s the purpose of the DLF, the data liberation Fund.

03:43

Speaker 1

So what we’re going to go through this morning, we going to cover a little bit of community news, just a few important updates. We’re going to go through some product news, which Teb and Lenny is going to take us through. We’re then going to have a look, fairly detailed look at the application that the diners team has put together. And then we’re going to have some q and a. We don’t have to skip any questions right to the end. We can actually, if you have any questions, please feel free to type in chat. Clarice is going to help keep track of those questions and we’ll try and answer those as we go along. So let’s try and make it a little bit interactive if we can.

04:24

Speaker 2

I see Charles has raised his hand.

04:26

Speaker 1

Charles has raised his hand. All right, Charles, let’s see what.

04:29

Speaker 6

Is there a question from Charles?

04:30

Speaker 2

No, just raise his hand. Not sure if he needs to find a button.

04:34

Speaker 1

The button does work. The raise your hand button does work. If you do have a question, let us know. Just a couple of thank yous and welcomes to some new customers. Over the last two months, we’ve added Agas, british american tobacco, doula first, quantum minerals, granule, passy, Ivan Platts, Interwaste, Johnson, workben, northern platinum, Vlans, nub technologies, Rio Tinto, Mozambique, SA Metel Group, Smiths Manufacturing, TWK, Agri and two Rivers platinum. Welcome to you guys. And yeah, welcome to the DLF community. Welcome to our ecosystem. Theres we got a couple of certifications. Yes.

05:19

Speaker 2

So in the last okay. Chat wasnt working.

05:23

Speaker 6

Okay. Awesome.

05:25

Speaker 4

Okay, thanks, Charles.

05:26

Speaker 1

Q and A is definitely working.

05:27

Speaker 6

Thank you. Yeah, good question. Yeah.

05:30

Speaker 2

So we had four new partners that joined our ignition certified community, foresight focus systems and software automation and systems in Satori in Cape Town. And then we also got a new gold partner, which is Devgatec in Cape Town. And yeah, two new flow certified partners, BCS Global and Zimbabwe, and also Zutori. So we are growing the community in the flow stuff. Just very exciting.

05:59

Speaker 1

Good stuff. Nice to have us flow certification in Zimbabwe as well. Yeah, that’s really good.

06:03

Speaker 5

Shows the community is growing. So yeah, very grateful for that.

06:07

Speaker 1

And well done to PCsloval as well. The team recently, they are now a named authorized distributive astronomy. I saw the certification.

06:17

Speaker 2

Premium distributor.

06:18

Speaker 1

Premium distributor. Very, very nice. Well done to you guys for that. We had a comment on some of our previous webinars that it’s great to see a link, but it’s nice to maybe, you know, scan a QR code while we’re live to access something. So you’re going to see these popping up all over the place. That’s what it is. It’s a QR code. Feel free to scan it. If you are interested to become a partner or just get a full view of our entire partner list, please do scan that to access our partner page. And of course Larissa is available should you want to join the program or have any questions about the system.

06:55

Speaker 6

Integrated program.

06:58

Speaker 1

Learning and enablement has never been more accessible. I nearly said easier. It’s definitely not easy to become certified, but it’s definitely more accessible than ever. We have three fairly intuitive platforms available to help learn all of the technologies. We have inductive university, the Canary Academy, and the flow masterclass. It is a really intuitive, easy way to get to know, familiarize yourselves with the technologies and get to understand a little bit more about it. Again, we’ll share those links afterwards, but it’s free to join. Please do so. In person training is of course available. These are just a view of some of our upcoming training courses over the next two months. We’ve just finished a series of training in Cape Town this week in fact, and KZN.

07:46

Speaker 1

So our upcoming courses for the next couple of weeks are all Joburg based, but again, that is available on our website to join us for in person training. A couple of helpful resources. There is a lot of information at the moment, there’s a lot of good documents, a lot of videos, lots of webinars happening. This is our pick for the last top three pick for the last couple of weeks. The first one is designed like a pro, which is actually a series of webinars by inductive automation. All around design philosophies, principles and pragmatic approaches to design. The most recent one is designing exceptional industry specific hmis. That was a very insightful one. Which data silos create a unified namespace? Hopefully everybody knows what a unified namespace is. I think we’re still trying to figure that out.

08:38

Speaker 1

It’s certainly an approach to industry that is becoming very popular and that webinar focuses exactly on that. How to build that unified namespace with ignition UDTs and MQTt. And then the third and final one is how to maximize manufacturing data with the smart KPI calculation engine. Then I really enjoyed that. I think it’s about a 15 minutes video. Really enjoyed that one in terms of how you could very quickly and easily, just by overlaying time on a couple of data points, get 15 to 20 KPI’s with minimal engineering lift. So that’s a really cool one, which we’ll share with you afterwards as well. You may or may not be aware, inductive automation has annual conference. It’s called the Ignition Community conference this year, similar to previous years. It will be hosted in Folsom in California again in October.

09:33

Speaker 1

What is quite different and bold, and maybe a little bit ambitious about this year’s one, is that they are adding a Spark plus Spark flash spark plug data dash to the ICC. So what’s it all about live during the ICC? They aim to bring up a cloud edition perspective dashboard. And they are inviting people, integrators, customers, home automation enthusiasts from all over the world to create some UDTS data model. UDTS perspective resources, basically feeding live MQTT data to their broker, which will be running in the cloud and they will be displaying the influx of that MQTT data live at the ICC. That’s very ambitious. Probably have several hundred, several thousand MQTT devices all feeding into that broker. So that’s going to be quite exciting to see.

10:28

Speaker 1

And the really cool part is that some of these community built udts and resources they will share on the ignition exchange afterwards, which is really nice. If you’re not familiar with the ignition exchange, it is a resource with. Sorry. It is a site with free ignition resources that you can download and use, saving you lots of time. It is vectored and certified by inductive automation. These are just some examples of some of the resources that’s available right now.

10:59

Speaker 5

There’s even a south african flavor on.

11:00

Speaker 1

This if you look at the bottom far right one. Yes, absolutely. I think de ring from advances, yes. Created the Eskimser push ignition integration very useful. I mean, it’s essentially you’ve got the 50 Eskimsa push calls a day and created a nice little interface to integrate with ignition and work around the load. We said we’re not going to speak.

11:24

Speaker 5

About load.

11:27

Speaker 1

But there’s a couple of really useful resources that’s available for free on the exchange, so we’ll share that link with you as well.

11:36

Speaker 6

Right.

11:36

Speaker 1

Some product updates. So inductive automation, I think ignition pushes version upgrades more than curtly. Oranger scores tries, but there’s a couple of versions that have been released over the last few weeks and months. We thought we’d take our time and maybe just share a couple of highlights to give you an idea. If you haven’t upgraded in the last two months or so, these are some of the highlights you can look forward to. Tebbie, do you want to maybe talk us through those?

12:06

Speaker 3

Yes, believe it or not, we’ve had five new versions since the last DLL we’ve had, so I’m going to quickly take you through the major updates that came out of the last four and then I’ll go through what we had.

12:21

Speaker 4

In the current version.

12:23

Speaker 3

So in 25 we have a live gateway network. And what that allows us to do now is it gives you a diagram in your status page, in your gateway pages page where you can see all of your different gateways and quickly diagnose what’s happening there. So you can see timeouts and actually transmit speeds so they can see what’s happening there.

12:43

Speaker 1

Visually, very nice. Yes.

12:45

Speaker 3

After that, the ignition team actually took the 25 version of ignition 1.8.1 .5 version of ignition to.

12:59

Speaker 1

Point to own, that is own white hacked hacker. It is.

13:04

Speaker 3

So basically they submit the products to a few white hat hackers to see.

13:09

Speaker 4

If there are any vulnerabilities.

13:11

Speaker 3

And those came back as purchased in 26.

13:15

Speaker 1

Okay, so nice and proactive.

13:17

Speaker 3

Makes it easier to make sure that.

13:20

Speaker 6

All the major security issues are solved.

13:24

Speaker 3

And then we have five new properties in the designer and gateway configs that under now manage timeout and data retrieval issues. So those will help with actually making sure that stop forward and that kind.

13:40

Speaker 6

Of issues are resolved. Right.

13:45

Speaker 3

Luckily we have in 28, we have a Mitsubishi driver which supports the Melsec. It’s called the Melsec protocol over TCP. And this is supported for the IQR and IQF range of Plc’s.

14:03

Speaker 6

Very nice.

14:04

Speaker 1

And I think the other one that was, I’m not sure if it was part of that release was the. Actually a couple of versions back was the IEC 61850. Yes. Driver that’s been added very much for substation automation.

14:17

Speaker 6

Cool.

14:17

Speaker 1

That’s a couple of important ones. And then the current latest, greatest. Eight 1.30.

14:23

Speaker 3

Yes, eight 1.30 in there. We have any component that has the path property now has a small button next to that property to take you.

14:33

Speaker 1

To the actual view, to the source.

14:35

Speaker 3

View where the component came from. So it makes it easier to actually identify where the component is. We also have a script cancel button security on that button.

14:45

Speaker 1

Now if you can do it, you.

14:47

Speaker 3

Can set it up in a way that if a person is not allowed to actually stop that script, you can hide or disable the button so that it wants to.

14:57

Speaker 1

That’s nice product.

14:58

Speaker 4

Yeah.

14:59

Speaker 6

Cool.

14:59

Speaker 3

So people who don’t have permission can be prevented from initially making changes that could break your system. We also have a few tags that have been, a few updates that have been made to our login for the tag historian to make it easier to actually evaluate what’s happening when we have pre processed history value tags.

15:20

Speaker 1

Okay, so that’s much better diagnosis there. Easier troubleshooting.

15:26

Speaker 5

Yes.

15:27

Speaker 3

And lastly, you might have noticed that we are at 30 and at 29. So what happened is we had a major regression that was in 29 that caused issues with able groups in the potting and that was fixed in 13.

15:42

Speaker 1

Nice.

15:43

Speaker 5

Yeah, good.

15:43

Speaker 1

That was quick.

15:46

Speaker 5

Fantastic.

15:47

Speaker 1

Thanks. So eight 1.30 is the latest version we do. We probably need a little more time. So what we’re going to do is we’re going to, over the next couple of weeks, schedule a follow up session. We’ve got the ignition cloud edition that went live AWS for now. Azure will follow. That was likely about a month ago or so there’s a lot to learn there and I think there’s a lot of opportunity there. So we’ll probably cover ignition Cloud edition separately. It’s worthwhile understanding the use cases. Ideal scenarios? Absolutely not ideal scenarios. So we’ll schedule something separately on Ignition Cloud edition. However, there is a lot of information available out on it already if you.

16:28

Speaker 6

Want to check it out. Okay, thanks, Siri. Thanks.

16:32

Speaker 1

Alrighty. Lenny. Version 6.1. Excitement. I’ve been told that this is groundbreaking. It is revolutionary, it is innovative. What are we doing?

16:47

Speaker 5

And just remember, I said it’s geeky. All right, so just a little bit of feedback on flow. We obviously, we developed a Microsoft, so the flow components was always developed on the.NET framework. We move to later versions, we moved to.net core.net core three to be exact.

17:08

Speaker 4

But that’s got end of life.

17:10

Speaker 5

So we needed to jump a bit to move pretty much the whole shebang to.net standard. So currently we moved everything to.net standard. Doesn’t sound like a lot, but what that allows us to do is we can now literally spin up a flow bootstrap with the engine, the message engine, the flow server, everything can now run on cross platform because.net is allowing us to do that. So we can run on Linux, we can run on Docker, we can even run on that little keyboard that’s there, that’s a raspberry PI.

17:46

Speaker 4

So we even got flow running on the Raspberry PI.

17:49

Speaker 5

Not something that I would advise in a factory environment, but it’s not just because you can, you shouldn’t. But it was just part of our testing to make sure we can run on the arm processes as well. So if you just allow me to share my screen. There we go.

18:08

Speaker 1

So you may have missed, while Leni is setting up, you may have missed that there is a, on the ignition exchange, there’s a couple of chat GPT resources and how you include use. How does chat DPT as a tool aid you in ignition development and building and scripting? And we’ve been speaking to a couple of people about that and we realized that hardly anybody knows what GPT stands for. So we’ve got a little poll. So for the first correct answer, or perhaps a lucky draw, or the first respondent, if you don’t know us, we enjoy fancy socks and we have a limited edition range of element eight canary flow ignition socks. We have an entire range to give away. So we are asking you to let us know, what does GPT stand for in chat GPT? Let’s see. That was quick.

19:09

Speaker 1

So the options are. Sorry, you have it on your screen, it’s not on our screen. The options are for the team, general purpose technology, group policy template and generative pre trained transformer. Those are the options. And I see that we’ve got a few more people. General purpose technology is up there.

19:27

Speaker 6

That’s scary.

19:31

Speaker 1

Policy template, no votes. Thank goodness for that. All right, should we call it? I think we can call it. Yes, let’s call it. So the correct answer is in fact generative pre trained transformer. So I am wondering, how do we select the winner for this? You can probably see on your side, I can’t. You can probably go to the participants that voted and see who the first. Okay, the reason. We’ll sort that off. Thank you for participating. But yes, the correct answer is in fact generative PTRA and transformer Lenny.

20:05

Speaker 6

All right, perfect.

20:07

Speaker 5

This is a beta version. So just to be aware this is a beta version of flow version 6.1.

20:15

Speaker 4

And I’ve got a platform here that.

20:17

Speaker 5

Is associated with my Linux environment. Currently it’s undeployed, so it’s not currently deployed. That’s what the greatest thing means, it’s not active on that box.

20:28

Speaker 4

All right, so I said it’s going.

20:29

Speaker 5

To get a bit nerdy. So we’re back.

20:32

Speaker 1

I’m back.

20:32

Speaker 5

It feels like I’m back in my high school days doing some.

20:39

Speaker 4

Exactly.

20:40

Speaker 5

Doing some DOS commands. But let’s have a look here quickly.

20:42

Speaker 4

So all I’m going to do now.

20:43

Speaker 5

Is just going to make sure that the flow service is actually running on Linux. I’m just doing a command here and.

20:48

Speaker 1

Then actually this is Ubuntu. Hang on.

20:49

Speaker 5

This is Ubuntu supporting Mister Shuttleworth. So in this case I just want to make sure that the flow boot the rap is actually running so we can just do a status on that from the system command. I’m not a Linux foolie at all, so we had to learn all of these things as well. So don’t be alarmed with the stuff.

21:14

Speaker 4

That we’re doing here.

21:14

Speaker 5

All right there we can see it’s not active. So the service is installed, but the service is not running, it’s inactive. If you look at the inactive command there.

21:25

Speaker 6

Let’s start it up.

21:26

Speaker 5

So I’m just going to start it up. So all we have to do here is change the status here to start flow up and it should come back and we should have a running flow bootstrap system. So that’s pretty much we will allow these, the tar files will be available to download to copy to the Ubuntu system. So we will prepackage those guys and that will be then available. All right, let’s just do the status again. There we go. Now it’s running. We’ve got an active running flow bootstrap. So let me just give a little bit of space here. So it’s going to clear and let’s deploy it. So I’m going to directly go and deploy this platform to that Ubuntu node. It’s got the flow message engine and a few other components. So notification services. So that’s going to start it up.

22:17

Speaker 5

Let’s go back to Ubuntu and let’s look at the status now. So you’ll notice that there it is. It’s busy starting up the platform. So the platform is starting up and if I do it again, we should see the other components as well starting up. So there’s the message engine, the notification server. So that is all now running on Linux. Cool, nice. As I said, a little bit geeky. I don’t know all the commands out of my head, so I’m just going to copy in my cheat sheet here. This is just literally to see what the bootstrap is doing in the back end. It’s a little of the error log that we always had in windows. So there I can see all the messages that’s getting executed on that side. Why are we excited about this?

23:07

Speaker 5

Well, if we want to run this in hosted environments in the cloud, Linux box is extremely cheap to start up, efficient. It’s much more efficient. So from a performance perspective, this is great.

23:20

Speaker 1

Be from an edge disparate remote edge point of view. There could be some benefit as well.

23:28

Speaker 5

100%, because one of the other components that we with this technology that we now will be able to support, sorry, this thing is now overlooked is if we go to Docker hub. So we also now have a Docker hub image for the flow. Jessica. So if I go to the hub library here.

23:49

Speaker 1

So maybe not everyone’s familiar with Docker containerization environment. Very popular. Ignition runs in Docker and in fact we run most of our development in different sandbox environments in Docker. Very, very popular.

24:02

Speaker 5

So you notice if you look for Flow Software Inc. We’ve got two repositories at this point. One is for the Arm version of the bootstrap, the one is just for the normal one. If I go to this, it will tell me how do I pull it from the docker. The latest version of the image from Docker. So I can use that command to pull it from Docker hub and then I can physically use this command to bound it to your local network and then just to set your time zone. And that should then run on Docker.

24:33

Speaker 6

Very, very nice. Cool.

24:34

Speaker 5

So I can quickly do this if I’ve got two minutes.

24:38

Speaker 6

You do? Absolutely.

24:40

Speaker 5

Let’s just stop the current service that’s in the Linux environment.

24:47

Speaker 6

All right. It’s fine.

24:50

Speaker 1

All right.

24:51

Speaker 5

And let’s pull it from Docker hub. So I’m physically going to pull the image from Docker. I’ve done this yesterday, so it’s probably going to be a little bit up to date. But this will pull the repository from Docker.

25:06

Speaker 6

All right.

25:06

Speaker 5

It’s probably going to tell me that it is up to date. There we go. The image is up to date. And now physically what I can do is I can go back to this command and this will physically run the image.

25:19

Speaker 6

Okay.

25:20

Speaker 1

So really makes it easy there.

25:24

Speaker 5

It’s going to go and start it up. It’s going to bound it to the local host and I will have a. There we go. That’s the id for the docker. If I now go docker stats, I should see my flow bootstrap running. Nice. I’m quite excited about this, especially from the resource perspective it’s using. Not a lot, nothing’s running. But from a resource allocation and processing perspective, this is great. So again, if I do exactly the same, I just underplay this guy and deploy it again. It’s physically going to go and start it up on that.

26:07

Speaker 6

Docker host. Cool.

26:10

Speaker 1

So there we can see it’s getting.

26:11

Speaker 6

A little bit more juice.

26:14

Speaker 1

It does run starting up. Very greedy.

26:17

Speaker 4

And then sorry, I’m going to cheat.

26:19

Speaker 5

A little bit again. But I do have my cheat sheet here for Docker as well. But I can also look at the docker containers, logs, copy and pasting is.

26:28

Speaker 1

Not cheating any repurposing.

26:32

Speaker 6

What is it?

26:32

Speaker 5

General transformer. And you can see it’s starting up my slack notification server. Starting up the message engine there.

26:42

Speaker 6

Lovely.

26:43

Speaker 5

So yeah, very excited, a little bit geeky.

26:46

Speaker 2

Sorry about that.

26:47

Speaker 5

But this opens up a whole lot of doors from a hosting perspective for sure. On local edge devices, connectivity as well.

26:55

Speaker 1

Definitely we see the environment within ignition, for example, what it means in terms of simplicity, spinning up time off, all of those things.

27:07

Speaker 3

Definitely see myself using this to quickly test multiple instances from different customers.

27:11

Speaker 1

I actually have a question from Charles. Charles Adams. Are there any plans to go to Docker as a platform?

27:18

Speaker 5

So the one thing that we still need to sort out is the actual configuration tool. So all the other components can run on Docker. It’s just the configuration tool at this point is still a Windows app, but 100% Charles, you can literally now go to a Linux environment, spin off rocker containers there and enable that. You just need to understand how Docker networking works a little bit as well, how to get it to your domains. That was also quite a steep learning curve for us to understand docker and docker networks. But yeah, from what we see from a performance perspective and from a management perspective, it looks like it’s definitely, those.

28:03

Speaker 1

Are the primary benefits.

28:04

Speaker 5

Exactly.

28:05

Speaker 1

For sure.

28:06

Speaker 6

Cool.

28:06

Speaker 1

Thanks Charles for your question. We’ll probably share a couple of resources around Docker in general, I think. And specifically for 6.1 linear, I think you’re inviting beta testers.

28:16

Speaker 5

Correct. So we’ve got a beta testing program out. If you want to get, if you want to be part of that, please feel free to contact the element 18, and we can get you on the list as well. So, yeah, it’s currently out for beta testing, especially for the Linux components.

28:31

Speaker 1

Okay. Feels like we need Rudy to do some testing for us as well. Rudy, you’re not busy at all. That’s cool. We’ll share some details for the Vita program. In fact, we’ve been showing some of those details on LinkedIn as well. Maybe that’s a good segue to our next. Before we do our next section, there’s maybe another poll. We’ve been speaking a lot about where we meet each other. And yes, we do this quarterly, every three months. We literally spend an hour together otherwise, day to day. So the first question is, beta software, do you like participating? And we’re trying to use the opportunity to get as much feedback as we can. Are you a typical beta tester? Do you enjoy doing beta testing? Do you? Not really.

29:25

Speaker 1

So the question is, do you like participating in beta testing or run beta software on your own devices, in your own testing or development or Qa environments? The options there are absolutely yes and no.

29:37

Speaker 5

Not really.

29:39

Speaker 1

So if you maybe want to give us some feedback on whether you typically run beta software.

29:47

Speaker 5

Bells. With a pros.

29:50

Speaker 1

Yes.

29:50

Speaker 6

Okay.

29:51

Speaker 5

Yes.

29:52

Speaker 4

Bells.

29:53

Speaker 6

Yes.

29:55

Speaker 1

Is anybody voting? I don’t see any votes on this one.

30:04

Speaker 2

Let me just quickly. Relaunchable.

30:07

Speaker 1

Oh, yeah. There was the results.

30:09

Speaker 6

There we go.

30:10

Speaker 5

All right, cool.

30:11

Speaker 1

Give us your feedback.

30:12

Speaker 6

It’s always nice to understand if I’m.

30:15

Speaker 1

Also going to vote. All right, so the results is coming in. We’ve got, we look like we have a beta sandbox testing community, which is great. We like that. We enjoy that. Okay, so it’s about 50.

30:36

Speaker 6

Yeah. Okay.

30:37

Speaker 1

It’s about 50. But it’s definitely the yes. The yes crowd is definitely winning this one. So that’s good to know. So it’s good to know that it’s valuable, that important part of software, not only development, but also getting feedback, early feedback, especially when we do new releases and new launches, that’s really key.

30:57

Speaker 6

Cool.

30:57

Speaker 1

Thank you for your feedback.

30:59

Speaker 6

And then maybe the next section that.

31:03

Speaker 1

We’Re going to go into. Let’s start with that. We’re actually good on time. Yes. All right, so these two gentlemen that have been sitting here very quietly observing a little bit shell shock by us, actually. Kunrad, Rudy, this is your project. This is your case study that you’re presenting today. Thank you so much for sharing it with us. I know it’s not always easy to get the various permissions and go ahead to be able to tell what you’ve done, but it is important to share not only the good work that you’ve done, but how you’ve done it. That’s often where a lot of the value lies. So we’ve got. Today we are chatting about Grindrod TCM. That is our case study for today. Please tell us a little bit more about it.

31:46

Speaker 7

Okay, so I was involved with the regional upgrade, well, the first upgrade in 2008, and we kept in touch with the customer. And over the years they had the requirement to upgrade a bit more. And then I think in 2020 we started engaging, or they actually engaged with us about replacing or changing from the old ET 200 and S 7300 range to the new Siemens range, and at the same time upgrading the ScADA portion as well. Since they have been using ignition on site for quite some time for other purposes than the SCaDA, they deemed it.

32:40

Speaker 6

The cost effective route to build on ignition SCADA.

32:46

Speaker 1

So they expanded on the existing ignition platform that was there, and they expanded that to the ScaDA. That’s fairly common. We do see a lot of that than migration from.

32:56

Speaker 7

We went through a couple of scenarios on what existing controls, but that to them was the more cost effective solution.

33:02

Speaker 1

Okay, so coal magnetite terminal in Mottola, Mozambique, part of the Grindrod group magnetite is interesting. I believe you still have some magnetites stuck in some metal parts somewhere on your bag.

33:18

Speaker 7

I think with my car. I drove a lot on site in 2008 when I was still allowed to magnetite in my car.

33:28

Speaker 5

I’m pretty sure.

33:29

Speaker 1

But fascinating operation. We’ll probably get a scale of it now when we look at some of the screens. So, yeah, the RISC was really a control system that needed desperate need for an update. And the solution that you deployed, hardware wise?

33:48

Speaker 4

Hardware wise, went to a seven 1500 PLC’s and upgraded from the old 300. So that meant because we wanted to use or upgrade the control. The whole control system, actually.

34:04

Speaker 1

The whole controls philosophy, really.

34:06

Speaker 4

Exactly, yeah.

34:07

Speaker 6

Yeah.

34:07

Speaker 4

So we decided to go to ignition and we had to basically rewrite all the software on the PLC’s as well. It’s not really necessary, but because we wanted to do a. A proper upgrade for them with a new control system or new SCADA system, we decided to do it that way. So, yeah, I think if we go into the detail, we’ll see why that.

34:33

Speaker 6

Was a good idea.

34:35

Speaker 1

That canary was deployed for long term visualization.

34:37

Speaker 6

Yes.

34:38

Speaker 1

And then flow for really some of the downtime, analysis, dashboarding and reporting needs and eventual integration into ERP, which I don’t think you’ve done yet.

34:48

Speaker 4

No, we’re busy with it. It’s ongoing at the moment, so we are busy with. We can also discuss some of those projects.

34:57

Speaker 6

Fantastic.

34:57

Speaker 4

On there.

34:59

Speaker 1

Look at some of the admissions curve we’ve got.

35:01

Speaker 5

Yeah.

35:01

Speaker 6

Okay.

35:02

Speaker 4

So this is actually the whole plant overview. So as you can see, if we start from the left of this data screen there we have some tipplers. So we are tipping train wagons and they have a whole bunch of conveyors and routes that eventually ends up first on stacker reclaimers, the three machines that you can see in the middle there.

35:25

Speaker 6

And then it ends up through the.

35:27

Speaker 4

Ship loaders onto a ship. So it looks fairly simple if you look at it on this overview. But these, I think 108 different routes.

35:37

Speaker 1

That they can cross potentially, yes.

35:41

Speaker 4

And I think that’s one of the.

35:43

Speaker 6

Biggest positives that came out of this project.

35:46

Speaker 4

So what they used to do originally with the old scalar system, they had what we call a root matrix.

35:56

Speaker 6

Sorry.

35:57

Speaker 4

So they had to go and look up what route they wanted to start with a number. They had to put that number in on a, like a set point almost, and then start that route. So what we’ve tried to do is simplify that. One of the good things about ignition is just the way you can integrate Python script in SQL. It’s just so easy.

36:18

Speaker 1

There’s a bit of fuzzy logic here to do to make this.

36:21

Speaker 4

Exactly. Yeah. So what we’ve done with SQL, because of the easy integration, we put all the routes into an SQL table. And then on the left where you can see there, we have like a source. We’ll go through that in a bit more detail as well. But then it’s much easier for them now to select the routes. They just select where they want to take material from where it should go. And then it gives you the options of what your available routes are to get to that destination.

36:52

Speaker 1

So the really smart part of this application is actually the route selection and optimization and visual one of them.

36:57

Speaker 4

Yes, we’ll get to it.

36:59

Speaker 6

Right.

36:59

Speaker 5

Stack a reclaimer.

37:02

Speaker 1

I learned not too long ago what is Stacker retainer was a couple of years ago. Before that I thought it was maybe a new burger. This is a stacker payment. For those of you that are not familiar with this environment, this is a stacker of. Maybe you can explain to us what happens here.

37:20

Speaker 4

Yeah, so this is how they get installed the material, if it comes from either train trucks or they have normal truck road trucks as well, which is a bit of a mess getting to the port traffic.

37:32

Speaker 6

Yeah.

37:33

Speaker 4

But we get there. So they stack material onto massive piles, and then they can reclaim it from the piles when there’s a ship to load.

37:44

Speaker 1

It’s a very manual process. Yes.

37:47

Speaker 4

So with these massive stack reclaimers, what they normally on the old system, they had a small little HMI in the cabin on the machine, and that’s how it was controlled. There was a little bit of data being seen through, like whether your boom conveyor is running those kind of things for interlocking between the PLC’s, but they couldn’t really see what was going on the machine except whether it was running or not. So now with ignition, we can pull in all of that data onto your main SCaDA system. So this is your main Scada picture from your main scada. What they see in the control room is exactly what the operator in the machine is seeing in the cabin.

38:27

Speaker 1

And the line view there is obviously a remote. Just a remote line.

38:30

Speaker 4

Exactly.

38:31

Speaker 6

Yes.

38:31

Speaker 4

We did opt for ignition edge on the machines so that it can run if there’s brakes in communication, because it makes redundancy. Yes. And it’s a movable machine, so it’s reliant on radio communication that is not always the most reliable. So if there’s a break in communication.

38:50

Speaker 7

Actually, there was a concern about the amount of data now all of a sudden being pushed through by ignition to the service.

38:58

Speaker 1

So radio network, what sort of numbers are we talking about?

39:06

Speaker 4

But it’s much more.

39:07

Speaker 7

It was drastically increased. We actually had a big thing about in the beginning, is the current radio.

39:14

Speaker 6

Network gonna handle this?

39:17

Speaker 7

And it worked.

39:18

Speaker 1

Beautiful.

39:19

Speaker 7

And it’s also, the radio network is since 2000, 819 somewhere there that they. It’s been running constantly.

39:28

Speaker 6

Okay.

39:28

Speaker 1

So that infrastructure is still sufficient for today.

39:31

Speaker 5

That’s great. And that’s using normal ignition gateway cons. That’s easy.

39:37

Speaker 6

All right.

39:38

Speaker 1

Because a natural thing when you, in that environment. MQTT could probably be an option as well.

39:42

Speaker 4

Yes, definitely.

39:45

Speaker 1

If your existing communication infrastructure isn’t sufficient.

39:48

Speaker 6

Yeah. Cool.

39:49

Speaker 1

Very nice.

39:52

Speaker 4

This is a ship loader. This is how the material then gets onto the ship. So very nice. Basically the same thing as on the stack reclaimer. This also has an edge panel in the cabin. But again, what you see on your edge panel, you can see on your skater in your main control room. So the other thing that was very helpful is, again, this was done through interplccoms before, but now, because every audio tag sits on your gateway. It’s very easy to display information from your main plant on your machine. So on your ship loader and vice versa.

40:30

Speaker 6

Yeah. Yes.

40:31

Speaker 4

So things that’s quite important for them. If you look at the analog right there under your general signals, the wind speed, that’s quite important. If your wind speed gets to around I think 80 kilometres an hour, it gets a bit dangerous to load ships and it’s important for the guys on site to know that and vice versa as well. So tonnagers, they were never able to see what they were loading. So the operator on the stack reclaimer for instance, was not aware what the other two stack reclaimers were doing, so he was just loading. And then sometimes they’ll have spillages on the belt because everybody’s reclaiming a lot and other times the one guy is slacking a bit and then you don’t know that. But now you can, everybody can see exactly what’s happening in the plant on your belt.

41:23

Speaker 4

If you can reclaim a bit more, maybe up reduction a bit without causing spillages on some bell.

41:29

Speaker 1

It’s amazing what the distability does to that information. We often speak about how that, when you’ve never had that visibility or that view once you have it, how that immediately improves process efficiency, reduce waste. Just having that view available, which is so important to readily have that information available. Very nice. And you mentioned the port side of.

41:53

Speaker 5

It, the ship side of it.

41:54

Speaker 1

I would imagine you can now share some of these views or maybe create a purpose view for that side of the operation which they’ve never had before, and maybe even integrate some of that.

42:06

Speaker 4

And that’s, as we mentioned earlier, some of the ongoing projects that we are utilizing flow for is specifically for that where we can now. So they had a system where every 2 hours they report their production figures.

42:22

Speaker 1

Every 2 hours.

42:23

Speaker 4

Yeah. On, via WhatsApp. So we are now automating that in.

42:28

Speaker 5

Flow so that every 2 hours we.

42:30

Speaker 4

Just send an email with the correct data. It’s not, there’s no more typing errors or anything like that.

42:38

Speaker 1

Human error.

42:38

Speaker 4

Human error, yeah.

42:40

Speaker 6

Interesting.

42:41

Speaker 4

So that’s, yeah, that’s quite nice. Okay, I think maybe we must go through this slide quickly. This is, we mentioned it a bit earlier for the root selections.

42:51

Speaker 1

And this is the operator root selection.

42:52

Speaker 4

This is the operator root selection. So as I mentioned that before, they had a root matrix consisting of 108 different routes. So they, I think most of the operators learned to learn the numbers. Some of the routes are probably routes that they don’t use often. So I think they. They started to learn, yeah.

43:12

Speaker 1

The optimal routes.

43:14

Speaker 4

The optimal routes and the most use routes. So they probably had those numbers sort of memorized, but for new operators or they can also easily make mistakes that way. So instead of having to manually look it up, what we do now is that first slide, you select the source. So you just click on that drop down, you select where you want the material to come from. Then you select your destination where it should go. And then on that middle drop down, it will give you all the available via roots. Okay, so this is. This is your options. You can go via this conveyor or via that conveyor.

43:50

Speaker 1

I’m going to go back quickly and I think that is actually. Then live on this view.

43:54

Speaker 4

Exactly.

43:56

Speaker 6

Yeah.

43:56

Speaker 4

So what happens maybe if you just stay on this slide. So what is also important for them? I know with the modern HMI, you actually don’t want to have too many different colors.

44:06

Speaker 1

We spoke about that first glance. You know what, we. We often find that there is such a big value on familiarity. So very often when we redesign and build something that is new, yes, the opportunity is new, but because of the value of familiarity, you know, we try and keep it as standard as it was.

44:24

Speaker 4

Exactly, yeah. So do not have to retrain the operators completely. On what? On the look and feel. It is quite a lot different than what it was. But the overall layout of the screen is exactly what they had. And it’s exactly because of that, so that you don’t have to retrain.

44:40

Speaker 1

I think it’s over time. You can probably introduce one once the familiarity is there. And that’s exactly the way the old system was. With no understanding of what’s running in the background. Then you can, over time, you can add some changes.

44:53

Speaker 4

Exactly. Because there’s also other challenges on a project like this, like the language barrier. I think now it’s a bit better from when you were there. Originally in 2008, we actually had to.

45:05

Speaker 7

Translate everything from English to Portuguese.

45:07

Speaker 6

Okay.

45:07

Speaker 1

You can’t speak Portuguese.

45:16

Speaker 4

Really important to ask over there. It’s more important to ask for a beer.

45:26

Speaker 1

So the green identified root is the current.

45:30

Speaker 4

Well. So if you look on the left hand side, on your group selections, you can see the different color arrows.

45:37

Speaker 5

Yes.

45:39

Speaker 4

Right at the top.

45:39

Speaker 1

Sorry, sorry.

45:40

Speaker 4

That side.

45:40

Speaker 6

Yeah.

45:41

Speaker 4

So you see the different color arrow. So as soon as you start your first route, it will always be green like that. And then your whole route will start up in a green color and you can see it running. So if the arrow is displayed, the complete route is running. If something on that route now stops, for whatever reason, the green for that stopped equipment. So, for instance, if we’re on the green one now, they’re from your excavators that stops.

46:07

Speaker 6

Yes.

46:07

Speaker 4

So then you’ll. Your green lines will disappear. And where it indicates that route on number 93, that arrow will also disappear. So then you know that route is not running anymore so that the guys can quickly see what is happening.

46:24

Speaker 1

Very, very nice.

46:25

Speaker 4

And, yeah, then as you start more and more routes, they will start filling up that table. So you can see there on route number 45, that route is not completely running. So something on that route probably stopped and now the guys can go and investigate what happened over there.

46:43

Speaker 1

A fair amount of logic that went into this.

46:45

Speaker 7

Yeah. Also very important where the roots are common equipment not to stop.

46:51

Speaker 4

To stop the route up into the.

46:53

Speaker 7

Point where the other route is still using.

46:54

Speaker 1

Yes. So you need to have that trigger or that event visibility.

47:00

Speaker 4

So you can see on this example now, so that pink route number or 100, is using some common equipment to the light blue one, which is why it’s not.

47:11

Speaker 5

Yeah.

47:12

Speaker 4

So if you stop that route, you must obviously now ensure that you don’t stop the equipment used for route 44.

47:19

Speaker 6

Yeah.

47:20

Speaker 4

Or if you stop route 44, then you should not stop the equipment running for route 100. And also, what is where the logic comes in. If you now stop that Cayenne or light blue route, the common equipment that is being used to then turn pink, because that’s how the route that is running. So there’s a bit of logic involved.

47:41

Speaker 1

And so a bit of logic, and I would imagine probably a fairly comprehensive alarming sub system as well.

47:52

Speaker 6

Well, sort of.

47:54

Speaker 4

But because ignition makes it so easy to do this with something like c scripting is probably. Well, it’s possible that’s what you guys did back in 2008. Now, you can use Python for that. You can now use. This was done before that, otherwise we might have.

48:15

Speaker 7

Be careful with JTPT. We’re not going to have a job.

48:21

Speaker 1

That’s very philosophical.

48:23

Speaker 5

I’ve got a different opinion.

48:24

Speaker 1

Yeah. It’s a tool.

48:26

Speaker 5

You need to know what to ask.

48:27

Speaker 6

Yeah.

48:28

Speaker 1

Somebody saw these line, also indicated the. Some of the. Some of the window. Yeah.

48:37

Speaker 4

So you can see the wind speed over the. Some small things that they didn’t used to have is per hatch, what they are loading, what the amount of material that they still have to go in each axe. Because with a ship, there’s a whole loading sequence of.

48:52

Speaker 1

And that happens when that ship is there. All focuses on that loading.

48:56

Speaker 4

Exactly. If you stop the loading while the ship is there, you’re in big trouble.

49:00

Speaker 1

Yeah. Then there’s all sorts of penalties and all sorts.

49:02

Speaker 6

Yeah.

49:02

Speaker 7

They’ve got lost the marriage. So they get three days.

49:07

Speaker 6

Really?

49:07

Speaker 4

Three days to load a ship. I’m not sure exactly the pains. They’ve got different sizes.

49:14

Speaker 6

Cool. Yeah.

49:16

Speaker 1

I am going to just to highlight.

49:19

Speaker 5

The matrix list in DB and then all the business rules kind of around this, the selection and the equipment. That’s all done within the python environment.

49:28

Speaker 4

Yes. It’s a combination of python and sql.

49:32

Speaker 5

Yeah.

49:32

Speaker 4

But most of that is, there’s still a lot of interlocks being done on the PLC side, of course.

49:38

Speaker 5

Yeah.

49:38

Speaker 4

So you want to keep your interlocks that side so that if you lose your scalar that you interlocking is at.

49:45

Speaker 1

Least integrating the business rules is key.

49:48

Speaker 6

Yes.

49:49

Speaker 1

If you want to. We’ll probably get to it. When we, when we look at the reporting side of it, understanding that the business rules already integrated into the logic that’s given us this value or this view of that number that’s been applied from inception, that makes a huge difference.

50:06

Speaker 4

That’s also some of the ongoing projects that we still have with the customer is exactly that implementing. So just to quickly explain that, for instance, your ship loading that ship will come with a loading plan to say what, of course.

50:22

Speaker 1

And there’s target associated with that plan.

50:24

Speaker 5

Yeah.

50:24

Speaker 4

So we’re busy putting all of that in. So that can be a more automated system as well. At the moment they are still from a excel sheet following that loading plan, but we’re busy implementing that as well directly into technician. So you can say this is your seed points and this is.

50:44

Speaker 5

Sorry, I’m laughing, I’m just remembering that ship that actually sank in Richards Bay because they loaded the one side too much and then it tippled over.

50:51

Speaker 6

Yes.

50:52

Speaker 5

Loading the band.

50:55

Speaker 1

That was not too long ago.

50:57

Speaker 6

Yeah.

50:58

Speaker 1

Right. So our silent hero canary running in the background.

51:04

Speaker 5

Yes.

51:05

Speaker 4

So what we’ve done here and for us, this is actually a very, I don’t want to say new, but a very exciting feature that we’ve been battling with other Skydar systems with for a while. And in ignition, I know it’s standard. So probably some of you more experienced ignition guys will say, well, this is common sense, but for us, the fact that you can pull in data onto ignition straight from canary. So all of our analog pop ups everywhere where you see a trend on ignition, it’s canary data and it’s what.

51:45

Speaker 1

Do you always say? Loosely coupled, tightly integrated. It’s just done through a couple of modules.

51:53

Speaker 5

Did you guys use the module?

51:54

Speaker 4

Yeah, it’s a module that’s not copchda.

51:57

Speaker 5

Comms and nonsense like that.

51:59

Speaker 4

It’s just a module. That’s why I’m saying for people that’s very familiar with ignition, this is basic stuff. But we wanted to include that because it’s not so basic on other platforms. This is one of the big things for ignition, where you can straight onto your scada, pull in data from your restoria. That’s not always possible.

52:22

Speaker 1

So two useful little pop ups, which is basically just the live spark spot.

52:28

Speaker 4

So that first one, this is our standard analog pop up. So if you click on any analog on your skater, this is the pop up that you’ll see.

52:35

Speaker 1

You can define the timeframe.

52:36

Speaker 4

And that’s the default time. So, yeah, so with a lot of the pop ups on Skada, if you especially analogs, it will give you just the analog value. And then you have a different button for your trend. But what we’ve seen is normally you want to see what happened at least the last ten minutes. If you click on analog value, you don’t want to see just that in some time.

52:58

Speaker 1

But you also want it to display and not wait. So you go make coffee and come back and maybe they did something on the screen.

53:04

Speaker 6

Yeah.

53:05

Speaker 1

Wanted to be responsive as well. Yeah.

53:07

Speaker 4

You click on that’s last 15 minutes. It’s updating live. So as long as you keep that open, it will keep updating.

53:13

Speaker 1

And from this view, you can actually see. You can access set points. Alarms.

53:17

Speaker 6

Yes.

53:17

Speaker 4

So your set points are there, your alarm settings.

53:20

Speaker 6

Well, sorry.

53:21

Speaker 4

That’s your actual alarm on this faulted for this specific analog. So set points you can see on the right hand side of that left.

53:30

Speaker 1

Hand offer you’ve got to identify.

53:34

Speaker 4

Really straightforward. But if you change your set points, then automatically your bar will get adjusted. This is also something we took from that high performance HMI philosophy, where you have a standard operating range. So that will be your green bar that you see on the bar there. But if you change your operating range, it will adjust your bar.

54:00

Speaker 1

I think that’s visually at least what we’ve learned. Come to understand as visually the best.

54:04

Speaker 6

Way of doing it. Definitely, yeah. Okay.

54:07

Speaker 4

And then on the other pop up on the right hand side, that’s basically the same data. It’s just now a more interactive trend where you can zoom in, zoom out, move your data around.

54:22

Speaker 6

Very nice.

54:22

Speaker 1

If anybody has any questions, now is the time to ask. Yeah, let’s carry on. Well done. Thank you.

54:30

Speaker 5

Nice. What I would like to see, Rudy, is you must do some regression analysis on that wind speed.

54:37

Speaker 4

Well, yeah, we can actually try and.

54:40

Speaker 5

See if we can predict if the wind.

54:43

Speaker 1

You can do some last projections, then.

54:46

Speaker 4

With wind it might be difficult.

54:48

Speaker 5

I think there’s even an exchange resource.

54:50

Speaker 1

Yes, there is.

54:51

Speaker 5

And the university health system. The regression analysis based on historical points.

54:56

Speaker 6

Yeah. Okay.

54:57

Speaker 1

It’s quite cool. Now, very important root cause analysis and actual life downtime classification inputs that you’ve defined that you’ve set up. Very nice. Maybe walk us through that.

55:10

Speaker 6

Yes.

55:10

Speaker 4

So again, with the help of Python scripting, it’s very easy for us to. If you stick to a standard naming convention, which we’ve done, we’ve tried to also implement the unified namespace. They did not really have a standard on site for their machines. It’s been built by different manufacturers and everybody sort of does their own thing. But now with an upgrade, we tried.

55:36

Speaker 1

To get them to have a unified and standards.

55:42

Speaker 5

Yes.

55:43

Speaker 4

So we’ll get to the udts in a bit.

55:46

Speaker 6

But because we are using that with.

55:48

Speaker 4

A specific naming convention, just with some simple string text manipulation, we can get certain pop ups. I can easily open pop ups. So this is on a motor. You have a process interlock pop up. This is what it will bring up. But then by following that naming convention, if you click on that. Well, this is just a slide now, but if you click the.

56:21

Speaker 1

We saw it live the other day, and I just want to click on it.

56:24

Speaker 4

If you now click, for instance, on more interlocks there, right at the bottom, your last interlock, it will take you to another interlock block. So you can daisy chain basically a lot of interlock blocks. And just with simple scripting, you can click, click on them until you get to your recalls analysis. So what’s happening here? You can see there’s three interlocks. That’s unhealthy, but the one with the purple dot, that’s the one that actually caused the trip.

56:51

Speaker 6

So while this motor was running, when.

56:54

Speaker 4

It stopped, that was the call. So it locks your first up interlock, and then if you look at your previous first ups, you’ll see the last two with a timestamp, because that’s also something that I haven’t seen in the industry that much, is that you have timestamps on your first up interlock. So you’ll have time step, but this really helps. And then you can see, was it actually this interlock that stopped your motor because now you can just pull up your canary trend and check. Does that correspond with those daytime states?

57:29

Speaker 6

Very, very nice.

57:30

Speaker 4

So, yeah, then on the downtime classification. So what we’ve done there for the, this is actually for the flow implementation on ignition. If any of your equipment stops, your main equipment, the operator immediately sees this pop up and he has to say.

57:49

Speaker 6

What the stop reason was, whether it.

57:52

Speaker 4

Was a plan or unplanned. And by selecting that will go into flow and then you don’t have to go into flow to do your stop classifications. You can do it from ignition and the data just gets pulled into flow.

58:04

Speaker 1

Absolutely. And that is also backfilled if not done at the time, unless it’s intellect. You can also backfill those reasons. Yes.

58:12

Speaker 4

And you can also go back to flow and change the stop reasons because this is now done by the operator because you want that first because they have to send two hourly updates. You don’t want to wait for the end of the shift, end of shift.

58:24

Speaker 1

Or end of day or.

58:25

Speaker 4

Yeah, for the production team or whoever to classify your stops.

58:30

Speaker 6

Very nice.

58:31

Speaker 4

But they can still go back and classify them. Split stops, all the normal flow functionality that you get.

58:38

Speaker 6

Nice. Okay.

58:40

Speaker 1

So I don’t know if we just want to spend too much detail getting into this.

58:44

Speaker 4

Yeah, no, I think I’ll just a quick explanation on this. Again, with python scripting, you can scan through all of your tags on your complete gateway. And so this is a basic filter, so we can go and derive a list of all your bypassed or simulated. You can expand this to have everything that’s in auto mode or in manual mode or everything that’s running for that instance.

59:09

Speaker 1

This is very expensive. I mean, how many do we have?

59:11

Speaker 6

A couple hundred? More than 100 signals?

59:17

Speaker 4

Yeah, yeah.

59:19

Speaker 1

Well, just building this.

59:21

Speaker 6

Yeah, yeah. So, yes, you can.

59:26

Speaker 1

What I mean is the logic around this.

59:28

Speaker 4

Yes, yeah, no, it’s quite a lot. It’s actually also not that difficult to do because you can just do it with scripting. If you have to do this on another system, it’s probably going to be tricky, it’s going to be very involved. But it’s easy to just scan through all your tags with a specific attribute. You look for that attribute and then you populate the list. So this is very helpful for the maintenance team where they can, they have a list which they can pull up weekly to see what is bypassed or what’s simulated in the plant and go and fix that. Unfortunately, you can’t pull the electrically bypassed equipment on here.

01:00:12

Speaker 5

When in doubt, bridge it out.

01:00:14

Speaker 4

Exactly. So that’s something. If somebody has a solution for that, we’re all ears.

01:00:20

Speaker 1

So this is very much where you spoke about standards earlier and building out some of those UDTs is very much where you’ve done that.

01:00:28

Speaker 4

Exactly. So this is another, I think, one of the probably top three biggest advantages of the way we’ve, I mean, it’s.

01:00:36

Speaker 1

A large body of work that you do upfront, but then it’s done and you repurpose it.

01:00:40

Speaker 4

Exactly.

01:00:40

Speaker 5

Yes.

01:00:41

Speaker 4

So what we’ve done in our PLC code, so we use UDP’s in the PLC and then because we are utilizing the OPC UA server on the PLC, there’s no need for DB offsets or address offsets. As long as you name on your ScaDA matches your name in your DB on your PlC, the link is made. So this is definitely one of the biggest advantages that we found because now you just create a tag on ignition.

01:01:14

Speaker 1

That instantiation takes care of the rest.

01:01:16

Speaker 4

And you pull it onto your skater and that’s done. It’s almost one seems so simple, but.

01:01:22

Speaker 1

It’S a fair amount of work.

01:01:23

Speaker 4

But it’s a fair amount of work.

01:01:25

Speaker 1

To get everything, the time saving that you have posted.

01:01:28

Speaker 4

Yes, exactly. Now, so once the initial development was done to engineer, now is easy. And for the guys on site as well, if they want to add a motor, it takes them three minutes to add a new motor.

01:01:41

Speaker 1

That’s the value of it.

01:01:43

Speaker 7

This project, this was a 3000 IO.

01:01:46

Speaker 5

Project, so doing it this way was quickest within the timeframe.

01:01:54

Speaker 1

Kalk engine is running. Low calc engine is running. Let’s have a look at a couple of reports. So daily operational.

01:02:05

Speaker 6

Yes.

01:02:06

Speaker 4

So this is some of the reports we are now sending on a daily.

01:02:10

Speaker 6

Nice, yeah.

01:02:13

Speaker 1

Your typical availability utilization.

01:02:15

Speaker 6

Yes.

01:02:16

Speaker 4

And again, like we discussed earlier, the nice thing about this is you can see that on the right hand side, your machine status, that now automatically comes from ignition.

01:02:25

Speaker 1

Yeah. Yes.

01:02:26

Speaker 4

It’s easy to do runtime and stop time on ignition or on your SCADA system, but those stop classifications because we are doing that on ignition immediately because the operator can’t stop the equipment if he hasn’t selected a stop reason for the previous stop.

01:02:46

Speaker 6

Correct.

01:02:46

Speaker 4

So that really makes. It forces them to do your stop classification. So immediately the data coming into flow is fairly accurate. If there’s, I mean, people can still make mistakes, so they still do sit shiftly or daily. I’m not sure how they do it at the moment to make sure that the stop classifications was indeed correct, because there can be mistakes. Again, they can split the stuff.

01:03:14

Speaker 6

But, yeah, I love.

01:03:16

Speaker 5

I love the calc for the meantime, between the fledges. That’s good.

01:03:20

Speaker 4

Yes.

01:03:22

Speaker 5

Would be interesting to see historically, if you can maybe reduce that or does it increase or whatever the case is. That’s a very good metric.

01:03:29

Speaker 4

Yeah. But if we can. If you have the metric, then you can start acting on it. So, still in the early days, but I’m sure we’ll. We’ll start seeing improvements on all of these metrics.

01:03:40

Speaker 6

Okay.

01:03:41

Speaker 4

This is the engineering of this.

01:03:44

Speaker 1

Very, very nice. So helpful.

01:03:47

Speaker 6

Yeah.

01:03:47

Speaker 4

So I really like that timeline, the event timeline app that we have in there that really gives you a good idea of what happened when.

01:04:00

Speaker 6

Yeah.

01:04:01

Speaker 1

Meantime, between failures.

01:04:03

Speaker 5

Very, very nicely.

01:04:05

Speaker 4

Then.

01:04:05

Speaker 1

You’ve designed one or two dashboards in your life.

01:04:09

Speaker 6

We get the lane approval.

01:04:12

Speaker 7

Any stamp of approval.

01:04:14

Speaker 5

Yes.

01:04:16

Speaker 4

Maybe you can. You can play around with the colors, but maybe make the right colors.

01:04:21

Speaker 5

Colors, for me, is not as important as just understanding what I see on the screen. So if I. If I have to give a comment, the only thing I would add here is just a caption around, what am I seeing for zero production? It’s daily production for a week, it seems like.

01:04:40

Speaker 4

Yeah, it’s the last thing you can.

01:04:42

Speaker 1

See it from the. From what’s measured, but it’s not that obvious.

01:04:45

Speaker 5

Yeah. So that’s for that. But other than that, the information is clear, the information is visible. It gives me what I. What I need to see.

01:04:52

Speaker 6

So.

01:04:52

Speaker 4

Yeah, well done. I struggle finding out what you’re looking at.

01:04:56

Speaker 6

Yeah, very nice. Yeah.

01:04:59

Speaker 4

The plan is also to put up some big screens all over the plant and recycle through.

01:05:04

Speaker 5

Just the visibility.

01:05:05

Speaker 1

Just the visibility. It’s such a easy one.

01:05:09

Speaker 6

Yes.

01:05:10

Speaker 1

Making that available.

01:05:10

Speaker 5

It doesn’t cost much.

01:05:11

Speaker 4

Yeah.

01:05:13

Speaker 1

Unless you have to buy client licenses, which we don’t. All right.

01:05:21

Speaker 4

This is just another production. And again, we’ve used that event timeline at the bottom so that you can see. So, basically, each line that you see there is when a train truck was tipped. So you can see it was producing fairly nicely in the morning.

01:05:37

Speaker 1

It was like an hour. The two hour run time.

01:05:39

Speaker 4

Yeah, lunchtime. And lunchtime carried on. It’s probably a Friday.

01:05:48

Speaker 7

We have something that we can just touch on. Circling back to ignition. Is ignition actually ties up with the train consignment.

01:05:56

Speaker 1

Okay.

01:05:57

Speaker 6

As the.

01:05:57

Speaker 7

As the train comes in, it’s got a consignment number, and the consignment shows them the amount of trucks and truck numbers. And that then they can. From the ignition side, they can have a drop down, automatically gets populated that’s.

01:06:10

Speaker 1

Not entered manually, that’s received from a database and that’s daily, I would imagine.

01:06:16

Speaker 6

Yes.

01:06:17

Speaker 7

And then ties also up with the interlocking when it tips.

01:06:22

Speaker 4

That’s not part of that ERP.

01:06:26

Speaker 6

Tools.

01:06:27

Speaker 4

That we’re still busy implementing that. But you’re right, the tipla one is actually fully implemented. So, like, very nice. They have to select wagon numbers from ignition, and that ties back to a database. And if there’s duplicates or they did not select the wagon number, it interlocks your tipler.

01:06:45

Speaker 1

Lovely. So that in itself probably removed the whole paper trail.

01:06:49

Speaker 4

Yes. They had a separate system from.

01:06:54

Speaker 7

Yeah. That wasn’t even interfaced with the world. The scale at that time, the system control system that time.

01:07:01

Speaker 5

So this made it very nice.

01:07:04

Speaker 6

Cool. Really appreciate it, guys.

01:07:08

Speaker 1

Thank you very much. Thank you so much for sharing. It’s always difficult to get somebody to probably more find the time to talk about what they’ve done.

01:07:17

Speaker 5

So I’m still back at the first thing about the magnetite.

01:07:22

Speaker 1

Yeah.

01:07:23

Speaker 5

So surely all of these things are metal, right. So is the magnetite, like, sticking everywhere?

01:07:28

Speaker 4

Middle piece of anything that’s magnetic?

01:07:31

Speaker 5

Yes.

01:07:32

Speaker 4

Okay, so the magnetite itself is not a magnet, but it’s magnetic. So if you put a magnetic property.

01:07:37

Speaker 1

Okay, so anything with a magnet in it.

01:07:40

Speaker 6

Yes.

01:07:40

Speaker 7

Like a handheld radio that use the communication. Yeah. You have to standing and open it up and then try and drag.

01:07:46

Speaker 5

So anything with a battery perhaps as well.

01:07:53

Speaker 4

So especially, like, the speakers in your.

01:07:55

Speaker 7

Car that I’m talking about. My car. Once I put it out there, I put it there.

01:08:04

Speaker 6

Cool.

01:08:05

Speaker 1

Awesome. Thank you very much for sharing. Yes. We had a question, I think, from Joe asking if we’re going to share the recording. Absolutely, we’re going to share the recording. If you have any questions, if you guys are okay with it, we’ll share Kunirat and Rudy’s details. Please let them know if you have any questions or want to get in touch and see how you can help it. Thank you again for sharing this one, guys. Really appreciate it. Just the last thing from our side, before we say goodbye or see if there’s any other questions, we will have some face to face events.

01:08:36

Speaker 2

Again, I’ll be first partner event.

01:08:40

Speaker 1

Yeah. We miss you guys. We’ve been having lots of get togethers, but we want to do something at scale, really. So in October, we will be in Cape Town.

01:08:49

Speaker 6

Yes.

01:08:50

Speaker 2

At the Haysel. Dole Wine estate.

01:08:53

Speaker 1

Hazel dull wine estate.

01:08:54

Speaker 6

Yes.

01:08:54

Speaker 2

In Kuala.

01:08:55

Speaker 1

We’ll be going to drink some wine and maybe talk a little bit of business.

01:08:57

Speaker 6

Yes.

01:09:01

Speaker 1

In October we are in Centurion.

01:09:03

Speaker 2

Yeah. At the Arini Farm lodge.

01:09:06

Speaker 1

So if you are a system integrator, you are a ecosystem partner, you’re an EPC, whatever you. We’re not choosy, we’re not selective. We open for anybody to join. Join us for the elevate event. There will be a technical focus, there will be a little bit more commercial and positioning focus and we’re excited to have some international people with.

01:09:27

Speaker 2

Yes, we can have Ken Melville from inductive.

01:09:30

Speaker 4

Ken Melville, he is the director of.

01:09:32

Speaker 2

Cells engineering, so he’s quite the ignition guru.

01:09:35

Speaker 6

Nice.

01:09:36

Speaker 1

We’ve got Lenny Smith, is it Smith? All the way from Texas.

01:09:44

Speaker 2

And they will have Clark and Kenan from Canary joining us as well.

01:09:50

Speaker 1

So we’ll send out. The website is live, we’ll share the link with where you can book with us, where you can schedule your reserve, your spot. And we will be adding a detailed agenda over the next couple of weeks. So we look forward to just checking in with everybody and having a community get together again. Any other questions for us? We’re a little bit over time. Twelve minutes over time.

01:10:14

Speaker 2

Yeah. Charles will send more details of the session about the events.

01:10:19

Speaker 1

There is already a page up with some details on the event.

01:10:21

Speaker 5

We’ll share it afterwards.

01:10:23

Speaker 1

Thank you for the question, Charles, another good question.

01:10:27

Speaker 6

Yeah.

01:10:27

Speaker 2

And just to get back to the GPT, our winner for that is the.

01:10:32

Speaker 4

Winner from Nauticon, Owen from Nauikon on the chat GPT.

01:10:36

Speaker 1

Well done.

01:10:36

Speaker 2

It was a good answer.

01:10:38

Speaker 1

Did you use.

01:10:42

Speaker 5

That was great.

01:10:44

Speaker 1